In the realm of heavy lifting applications, the significance of Rope Block Sheaves cannot be overstated. These essential components are a critical part of lifting systems, influencing efficiency, safety, and operational effectiveness. According to a recent industry report by the Heavy Lifting Equipment Association, the demand for robust and innovative sheave technology is expected to grow by over 15% annually as industries increasingly rely on advanced materials and design advancements to enhance load handling capabilities.

Industry expert Dr. Samuel R. Thompson, a respected figure in the field of mechanical engineering, highlights the importance of proper sheave selection, stating, "The performance and longevity of lifting systems largely hinge on the quality of Rope Block Sheaves employed." As organizations strive to optimize their lifting operations while ensuring maximum safety, understanding the specifications and applications of different sheave types becomes paramount. This guide aims to provide comprehensive insights and practical recommendations for selecting the most suitable Rope Block Sheaves for various heavy lifting scenarios by 2025, thereby assisting industry professionals in making informed decisions that adhere to evolving standards of performance and reliability.

Top rope block sheaves play a critical role in heavy lifting applications, facilitating the movement of hefty loads with ease and efficiency. These components, designed to guide cables or ropes, are essential in various industries including construction, shipping, and manufacturing. By using sheaves, the friction experienced during load movement is significantly reduced, which not only increases operational efficiency but also enhances safety. The design of these sheaves can vary depending on the specific application, with considerations for load capacity, material durability, and resistance to environmental factors.

In addition to their fundamental role in load management, top rope block sheaves are integral to lifting systems that require precision and control. Their application is widespread, from crane operations to winching systems, where reliable performance is paramount. The choice of the correct sheave type and size can directly influence the effectiveness of a lifting operation. Understanding the compatibility of sheaves with different ropes and the conditions under which they will be used is essential for maximizing their functionality and service life, ultimately contributing to seamless heavy lifting operations.

| Sheave Type | Material | Max Load Capacity (tons) | Sheave Diameter (inches) | Applications |

|---|---|---|---|---|

| Single Sheave | Steel | 10 | 8 | Basic Lifting |

| Double Sheave | Aluminum | 15 | 10 | Construction |

| Triple Sheave | Composite | 20 | 12 | Heavy Machinery |

| Heavy-Duty Sheave | Steel | 25 | 14 | Industrial Lifting |

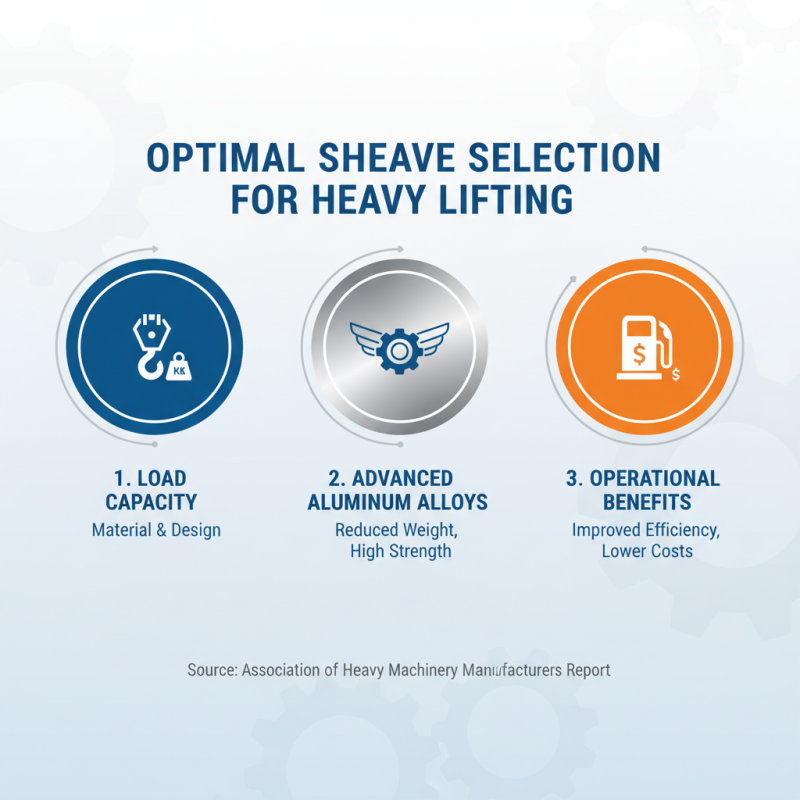

When selecting sheaves for heavy lifting applications, several key factors must be considered to ensure optimal performance and safety. One of the primary factors is load capacity, which is directly influenced by the sheave's material and design. According to a report by the Association of Heavy Machinery Manufacturers, sheaves made from advanced aluminum alloys can offer a significant weight reduction while maintaining high strength levels. This is crucial in heavy lifting scenarios where every kilogram matters, as reducing the overall weight of the rigging system can lead to improved fuel efficiency and decreased operational costs.

Another critical factor is the sheave diameter, which affects the bending moment on the rope or cable being used. Industry standards, as outlined in the International Organization for Standardization (ISO) guidelines, recommend that the sheave diameter be at least 20 times the diameter of the rope to prevent undue stress and promote longevity. Additionally, the groove design of the sheave plays a vital role in reducing wear and tear on cables. A recent study published in the Journal of Mechanical Engineering highlighted that properly designed groove profiles can decrease friction and enhance cable durability, extending replacement intervals and minimizing downtime.

Lastly, environmental conditions cannot be overlooked. Heavy lifting applications often encounter harsh environments, and material selection for sheaves must account for factors such as corrosion resistance and temperature fluctuations. The American Society of Mechanical Engineers (ASME) emphasizes the importance of using sheaves with appropriate coatings or materials that can withstand exposure to various elements, ensuring reliability and safety in critical lifting operations. By carefully evaluating these factors, professionals can make informed decisions that enhance the efficiency and safety of their heavy lifting applications.

When selecting block sheaves for heavy lifting applications, material strength plays a crucial role in ensuring durability and safety. According to a report by the American Society of Mechanical Engineers (ASME), the sheave's material must withstand not only the static load but also dynamic forces that arise during lifting operations. For instance, the shear strength of high-grade steel sheaves can range from 370 to 580 MPa, making them suitable for high-capacity lifting tasks. In comparison, lightweight materials like aluminum, while beneficial for weight reduction, often exhibit lower tensile strength, with values typically around 270 MPa, which necessitates careful consideration when evaluating load requirements.

Moreover, industry standards, such as those outlined by the International Organization for Standardization (ISO), suggest that factors such as environmental conditions, corrosion resistance, and fatigue limits should also be evaluated when assessing sheave materials. For heavy lifters operating in harsh conditions, using corrosion-resistant materials, such as stainless steel or specialized coated alloys, can enhance longevity and reliability. In fact, a study published in the Journal of Materials Science indicates that using advanced composite materials, which can possess tensile strengths exceeding 700 MPa, is becoming increasingly popular, offering enhanced durability and resistance to fatigue failures, thus improving overall operational safety in critical applications.

When it comes to heavy lifting applications, understanding load ratings and safety factors is paramount to ensure reliability and prevent accidents. Load ratings refer to the maximum weight that a rope block or sheave can handle under optimal conditions. These ratings are determined through rigorous testing and engineering calculations, taking into account various factors such as material strength, design configuration, and intended use. It is essential for operators to always refer to these ratings, as exceeding them can lead to catastrophic failures and potentially dangerous situations.

Additionally, safety factors are critical in heavy lifting operations, serving as a buffer between the maximum load capacity and real-world applications. A safety factor is essentially a multiplier applied to the load rating that accounts for unforeseen circumstances, including dynamic loads, environmental conditions, and wear over time. By incorporating appropriate safety factors, operators can significantly reduce the risk of equipment failure. For instance, a safety factor of 5 means that a block rated for 1,000 pounds could theoretically handle up to 5,000 pounds before failure, providing an added layer of security during lifting operations. Ensuring that the chosen sheaves and blocks meet both load ratings and safety factor requirements is essential for dependable, efficient, and safe heavy lifting practices.

The evolution of rope block sheave technology is poised to significantly impact heavy lifting applications by enhancing efficiency and safety standards. Recent industry reports indicate that advancements in materials science, particularly the introduction of lightweight yet durable composites, can improve the performance and longevity of sheaves. A leading analytical report projects a potential 30% increase in sheave lifespan when utilizing advanced polymer compounds compared to traditional materials. This not only reduces replacement costs but also supports sustainability initiatives by minimizing waste in heavy lifting operations.

Moreover, the integration of smart technology in rope block sheaves is rapidly gaining traction. Equipped with sensors and IoT capabilities, these modern sheaves can provide real-time monitoring of load weights and rope conditions. According to a study by industry experts, the adoption of smart sheave technology is expected to grow by over 50% by 2025, driven by the need for enhanced safety protocols and operational efficiency. This trend toward digitalization in heavy lifting not only promotes better decision-making but also minimizes the risk of accidents caused by equipment failure or miscalibration. As the sector continues to embrace these innovations, the future of rope block sheave technology looks increasingly promising, reinforcing its critical role in heavy lifting applications.