In the dynamic world of hydraulic systems, innovations in Hydraulic Pump Units are crucial. Renowned expert Dr. Emily Johnson, a leader in fluid mechanics, emphasizes, "The future of hydraulic technology lies in efficiency and smart integration." As we look to 2026, advances in Hydraulic Pump Units are becoming more evident.

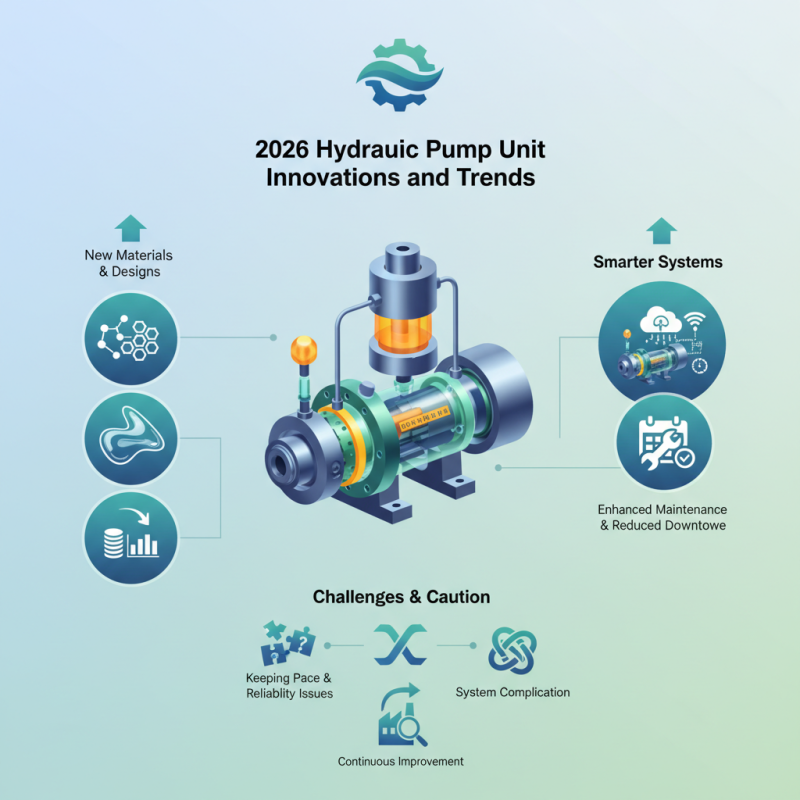

Manufacturers are exploring new materials and designs. These changes improve efficiency and reduce costs. However, the industry still faces challenges. Many companies struggle to keep pace with rapid innovations. Some units may not perform as expected, leading to reliability issues. Reflecting on this, specialists urge companies to embrace continuous improvement.

The trends show a shift towards smarter systems. Incorporating IoT allows for real-time monitoring. This enhances maintenance and reduces downtime. Yet, the industry must remain vigilant. Not all innovations lead to progress. Some might complicate systems rather than simplify them. As we enter 2026, the journey of Hydraulic Pump Units will be one of caution and ambition.

Hydraulic pump units play a vital role in various industries. They are used in construction, manufacturing, and agriculture. These pumps facilitate the transfer of liquids under pressure, powering machinery and tools. Without them, many operations would grind to a halt. Their efficiency directly impacts productivity.

Innovations in hydraulic pump technology have led to more compact designs. This saves space and reduces installation costs. However, these advancements can also create challenges. Smaller units may encounter overheating issues. Failure to address this could result in equipment failures. Users must approach these innovations with caution and careful study.

Application versatility remains a key benefit of hydraulic pump units. They adapt to different tasks, providing reliable performance. However, operators need to understand the limitations of each unit. Overuse can lead to maintenance problems. It's essential to strike a balance between capability and durability. Each application has its unique requirements that should be thoroughly evaluated.

The landscape of hydraulic pump design is shifting dramatically. Innovative technologies are emerging, transforming traditional thinking. For instance, digital twin technology allows for real-time monitoring and optimization. This method helps engineers understand performance under various conditions. Furthermore, it enhances predictive maintenance, reducing downtime.

Another significant trend is the integration of smart materials. These materials adapt and respond to environmental changes. They enable hydraulic systems to become more efficient and responsive. Imagine pumps that can automatically adjust pressure based on the load. This technology could lead to substantial energy savings.

However, challenges remain in implementation. Many designs may not meet existing standards. Additionally, the transition to these advanced technologies can be costly. Companies need to consider the return on investment carefully. Balancing innovation with practical application is essential for future success. The ongoing exploration of these technologies invites reflection on potential limitations.

Sustainable practices in hydraulic pump unit design are gaining momentum. The industry's focus is shifting towards reducing carbon footprints. A recent industry report highlights that up to 70% of hydraulic systems in use today waste considerable energy. This inefficiency leads to increased operational costs and environmental concerns.

More manufacturers are exploring eco-friendly materials. Many newer pump units utilize recycled components. This shift is not just about materials; it also includes energy-efficient designs. Implementing variable-speed drives can lower energy consumption by 50%. Some companies report significant reductions in greenhouse gas emissions after adopting these technologies. However, not all sectors embrace this change quickly.

The challenge lies in balancing performance and sustainability. Hydraulic pump units must function reliably while minimizing impact. The pressure is on the industry to innovate. Effective recycling systems for old units remain underdeveloped. Until solutions are widespread, the environmental burden continues. There’s much work ahead to align innovation with ecological responsibility.

The hydraulic pump industry is evolving rapidly. Innovations focus on enhancing efficiency and performance. Future designs aim for lower energy consumption. New materials and technologies play a crucial role. These advancements promise to reduce waste. However, some challenges remain.

Current trends show a move towards smart pumps. These devices can adjust based on system demands. This adaptability can lead to significant energy savings. Yet, implementing smart technology may pose integration issues. Maintenance practices must adapt to these new systems. Training for technicians will also be essential.

Another notable trend is the push for enhanced durability. Hydraulic pumps face harsh conditions. Improving material strength is vital for longevity. However, durability can sometimes lead to increased weight. This trade-off requires careful consideration. Balancing performance and practicality is not always straightforward. New innovations must strive for both efficiency and reliability.

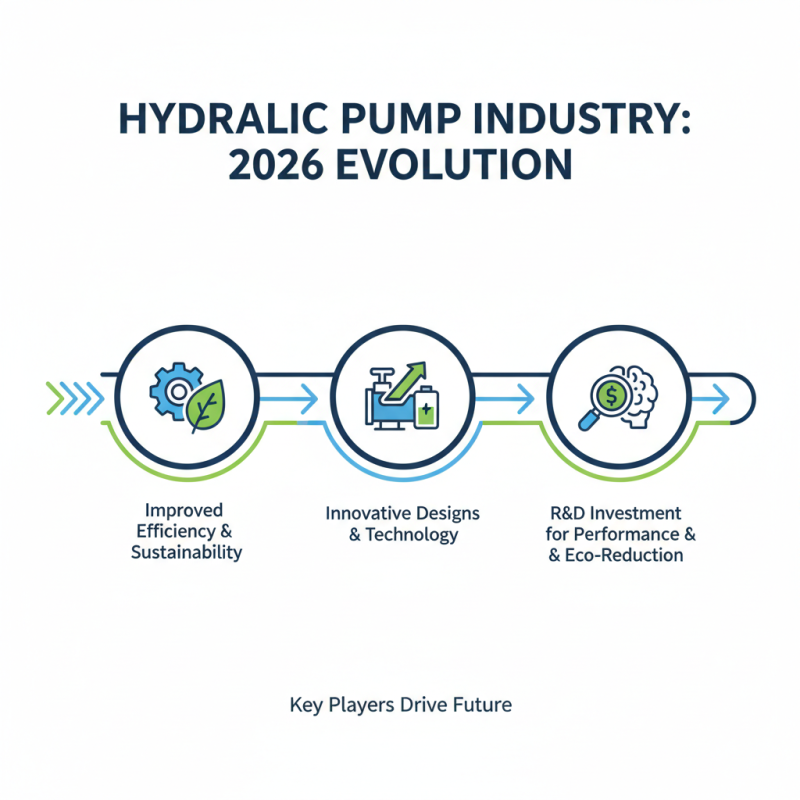

The hydraulic pump industry is evolving rapidly. Key players are embracing innovative designs and technologies for 2026. These advancements focus on improved efficiency and sustainability. Market leaders are investing heavily in R&D. They aim to enhance performance while reducing energy consumption.

Tips: Focus on energy savings. Evaluate the noise levels of new models. User feedback is essential. It helps identify effective solutions and areas for improvement.

Many companies prioritize smart technology integration. This allows for real-time monitoring and predictive maintenance. However, some projects struggle with implementation. It's crucial to review challenges and learn from them. Lastly, user experience must stay at the forefront of innovation. Engage with end-users to understand their needs and pain points.

Tips: Conduct regular surveys. Analyze user satisfaction consistently. Small changes can lead to significant improvements. Remember, innovation is a journey, not a destination.