In the ever-evolving landscape of drilling operations, effective fluid management is crucial for optimizing performance and ensuring safety. One of the essential components in this domain is the Drilling Mud Pumps, which play a pivotal role in the circulation system of drilling rigs. These pumps are designed to handle the complex dynamics of drilling fluids, ensuring that the necessary pressure is maintained and that the cuttings are efficiently removed from the wellbore. As the demand for efficient and reliable drilling solutions grows, selecting the right Drilling Mud Pumps becomes increasingly important for operators looking to enhance their drilling efficiency and minimize downtime.

This article delves into the top 10 best Drilling Mud Pumps available in the market, focusing on their features, capabilities, and overall performance. By examining these pumps, we aim to provide insight into how these technologies can streamline fluid management processes, improve operational effectiveness, and contribute to successful drilling outcomes. Whether you are new to the industry or a seasoned professional, understanding the diversity and innovations in Drilling Mud Pumps will empower you to make informed decisions that align with your specific drilling needs.

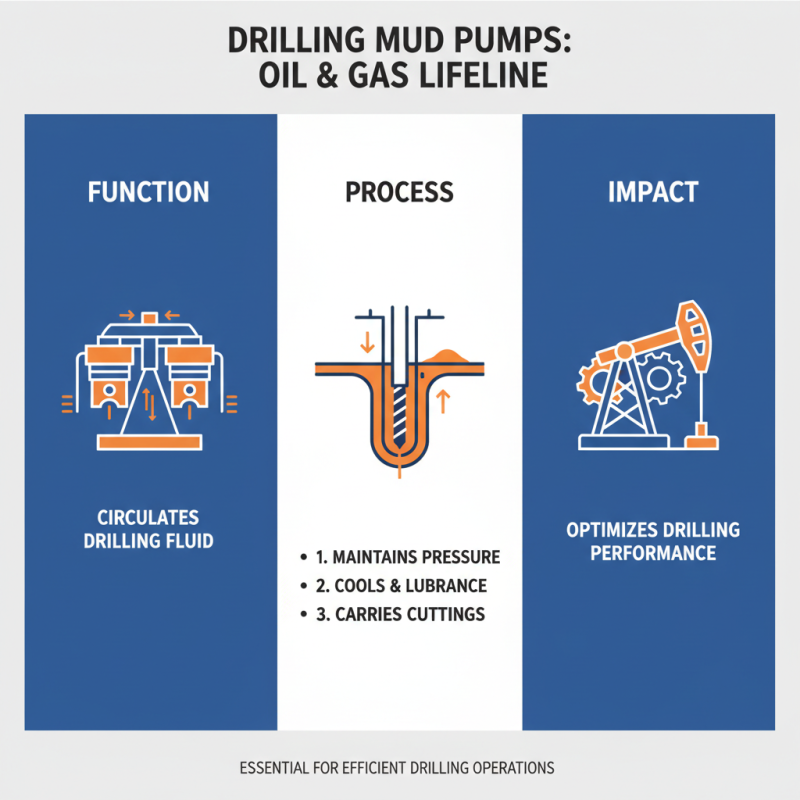

Drilling mud pumps play a crucial role in the oil and gas industry, primarily aiding in the circulation of drilling fluids during drilling operations. These pumps are designed to maintain the necessary pressure to transport drilling mud from the surface to the drill bit. By ensuring proper fluid flow, they help in cooling and lubricating the drill, as well as in carrying away cuttings to the surface. The efficiency of a drilling mud pump directly impacts overall drilling performance, making it vital for operators to understand their functionality.

The design of drilling mud pumps varies, but they generally fall into two main categories: centrifugal and positive displacement pumps. Centrifugal pumps utilize rotational energy to move fluids, making them ideal for high flow rates but less effective in handling heavy slurries. On the other hand, positive displacement pumps are engineered to deliver a consistent volume of fluid regardless of the system pressure, providing an advantage when managing thicker muds. Key factors in evaluating these pumps include flow rate, pressure capabilities, and their ability to handle differing viscosities of drilling fluids, all of which are essential for effective fluid management during drilling operations.

When selecting a high-performance drilling mud pump, key features play a crucial role in efficient fluid management within drilling operations. One of the most critical aspects is the pump’s flow rate capacity, which typically ranges between 200 to 2000 gallons per minute (GPM), depending on the specific application needs. According to industry reports, pumps with higher flow rates can significantly reduce downtime and increase overall drilling productivity by ensuring continuous circulation of drilling fluids. Additionally, the ability to handle a wide range of viscosities is essential, as drilling mud often varies in consistency based on the geological conditions encountered.

Another vital feature to consider is the pump's pressure rating, which should be able to withstand the demands of high-pressure applications commonly found in deep drilling scenarios. Modern pumps often have pressure ratings exceeding 2500 PSI, providing the necessary force to deliver mud to the surface effectively. Furthermore, efficiency is greatly enhanced by selecting pumps designed for easy maintenance and quick part replacements, which is essential for minimizing operational disruptions. The incorporation of advanced materials, like hardened steel and composite alloys, also contributes to longevity, reducing wear and tear over time. Ultimately, focusing on these key features ensures that drilling operations can achieve optimal performance and reliability in fluid management.

When evaluating the top brands in the drilling mud pump market, it's essential to consider factors such as performance, durability, and efficiency. The variety of pumps available often caters to diverse drilling conditions and fluid management requirements, making it crucial for operators to choose wisely.

High-performance mud pumps can significantly impact the overall success of drilling operations by ensuring optimal fluid circulation and effective removal of cuttings.

In comparing leading brands, one should focus on their technological advancements, customer support, and service options. Many manufacturers leverage cutting-edge engineering to enhance their pumps' reliability and longevity. Additionally, the availability of customizable options allows for tailored solutions that meet specific project demands. As competition in the market grows, companies are increasingly investing in research and development, resulting in innovative designs that improve operational efficiency while minimizing maintenance costs. The landscape of drilling mud pumps continuously evolves, emphasizing the need for operators to stay informed about the latest trends and advancements within the industry.

Maintaining drilling mud pumps is crucial for ensuring their efficiency and longevity. Regular inspections should be a part of every maintenance routine, focusing on key components such as seals, bearings, and hoses. A thorough visual check can help identify any signs of wear or damage, which may lead to larger problems if not addressed promptly. It's also essential to monitor the fluid levels and quality regularly; contaminated or insufficient fluid can lead to pump inefficiency and increased maintenance costs.

Tips for enhancing pump performance include implementing a schedule for regular oil changes and checking for any leaks that could impact functionality. Using high-quality filtration systems can prevent impurities from entering the pump, ultimately extending its service life. Additionally, operators should get familiar with the manufacturer’s maintenance guidelines to ensure all recommended practices are followed closely, as these can vary based on specific pump models and applications.

Another key consideration is ensuring proper alignment and coupling of the pump to its motor, as misalignment can cause excessive wear and energy loss. Operators should also ensure that the pump is operating within its design parameters and not exceeding recommended speeds or pressures. Following these best practices will result in improved operational efficiency and a longer lifespan for your drilling mud pump, contributing to the overall success of your fluid management efforts.

The landscape of drilling mud pumps is undergoing a transformative shift, driven by innovative technologies that are enhancing fluid management in the drilling industry. One of the most notable advancements is the integration of smart sensor technology, which allows for real-time monitoring of pump performance and fluid characteristics. This data-driven approach not only optimizes the pump operation but also enables operators to predict maintenance needs, reducing downtime and enhancing efficiency.

Another significant breakthrough is the development of energy-efficient pump designs that minimize power consumption while maximizing output. These pumps often utilize advanced hydraulic systems and materials that reduce weight and improve durability, resulting in lower operational costs. Moreover, the incorporation of automation and artificial intelligence in pump management systems is for streamlining processes, allowing for smarter decision-making and improved safety protocols on drilling sites.

As these technologies continue to evolve, the future of drilling mud pumps looks promising, paving the way for more sustainable and efficient fluid management solutions in the oil and gas industry.