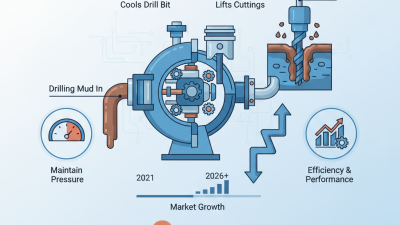

Choosing the right drilling mud pumps is crucial for the success of drilling projects. According to a report by Grand View Research, the global drilling mud pumps market is expected to grow significantly in the coming years. This growth emphasizes the importance of selecting pumps that meet specific project needs.

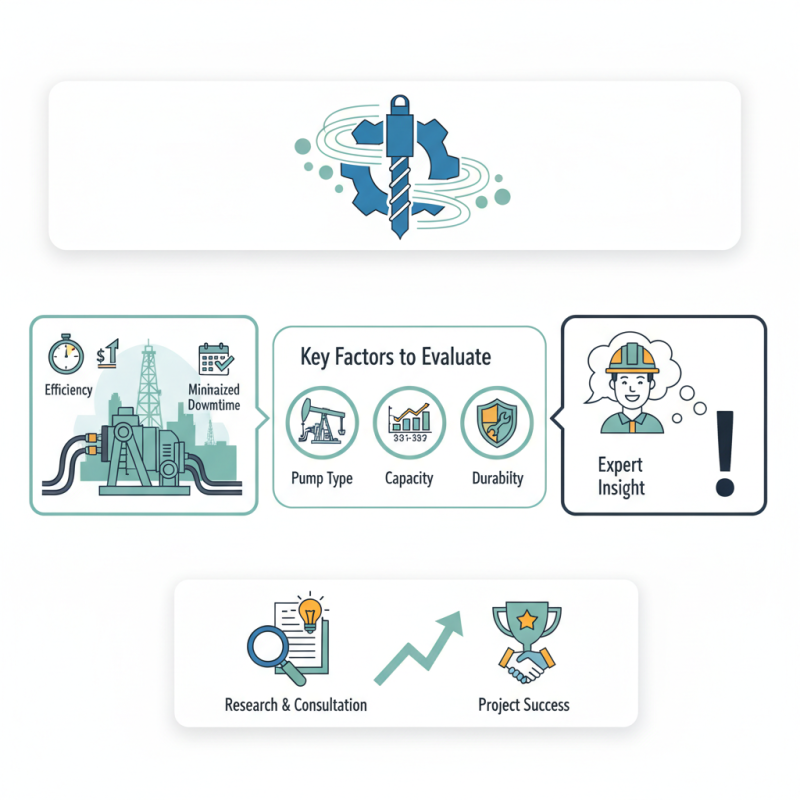

Expert John Peters, a renowned figure in the drilling industry, asserts, "Selecting the right drilling mud pumps can make or break your operation." This highlights the critical role these pumps play in maintaining efficiency and cost-effectiveness during drilling. Poor choices may lead to increased downtime and project delays, which can be costly for companies.

Drilling mud pumps are vital for transporting drilling fluids. The right pump ensures optimal performance and minimizes wear and tear. However, it’s essential to evaluate various factors such as pump type, capacity, and durability. A common mistake is overlooking these details. Ultimately, investing time in research and consultation can lead to better outcomes and project success.

When planning a drilling project, the role of drilling mud pumps is crucial. These pumps circulate drilling mud, which cools the drill bit and carries cuttings to the surface. A reliable pump ensures consistent flow and pressure. It can significantly affect drilling efficiency.

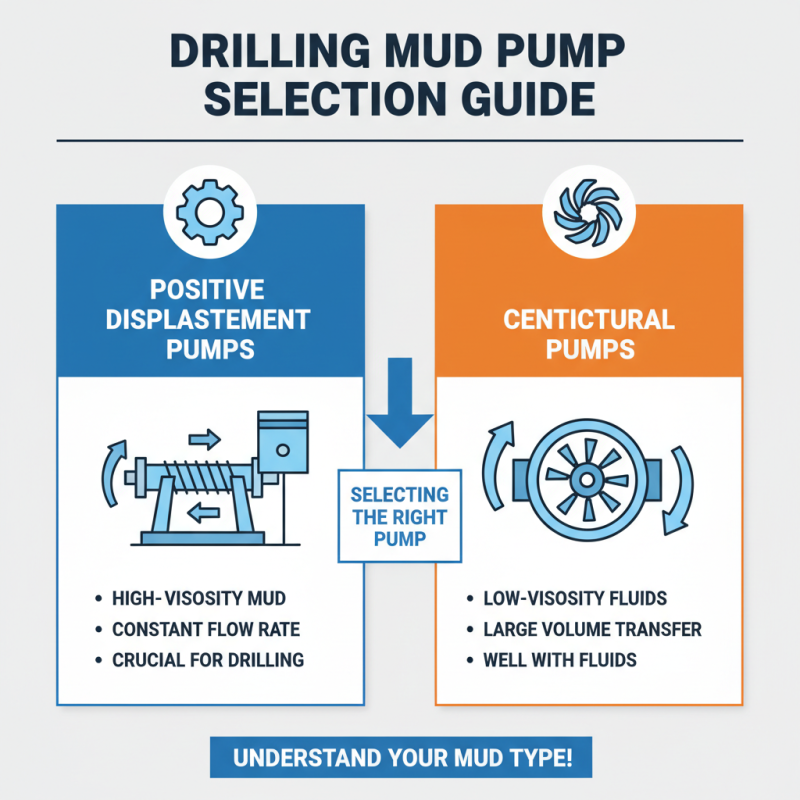

Drilling mud comes in various formulations. The suitability depends on project specifics. A pump must handle the viscosity of the chosen mud. If the pump is undersized, it may lead to delays. Over time, wear and tear can decrease efficiency, making maintenance vital. Think about the pump’s energy consumption as well. Some pumps may consume excessive power, impacting budget and sustainability goals.

Selecting the right size is essential yet often overlooked. Many projects face setbacks due to inadequate pump capacity. It's easy to assume that bigger is always better. However, an oversized pump can waste resources too. Balancing size and performance demands careful assessment. Evaluating these factors can improve project outcomes, but many teams still make common mistakes. They often rush decisions, leading to unanticipated challenges.

| Pump Type | Flow Rate (GPM) | Pressure (PSI) | Power (HP) | Applications |

|---|---|---|---|---|

| Positive Displacement Pump | 30 - 300 | 100 - 1500 | 15 - 50 | Heavy drilling, well services |

| Centrifugal Pump | 50 - 800 | 30 - 300 | 5 - 30 | Mud circulation, support operations |

| Diaphragm Pump | 10 - 150 | 50 - 800 | 2 - 15 | Suction lift applications, low flow |

| Submersible Pump | 20 - 400 | 50 - 1000 | 10 - 40 | Water drainage, slurry applications |

| Gear Pump | 15 - 250 | 20 - 600 | 3 - 20 | Viscous fluids, precise flow control |

When selecting drilling mud pumps, understanding the types available is crucial. There are positive displacement pumps and centrifugal pumps. Each type has its unique strengths. Positive displacement pumps are ideal for high-viscosity mud. They provide a constant flow rate, essential for most drilling operations. On the other hand, centrifugal pumps work well with low-viscosity fluids. They are generally used for large volume transfers.

Applications vary widely between these pump types. For example, positive displacement pumps are often found in remote drilling sites with thick mud requirements. They handle pressure changes effectively. Centrifugal pumps are frequently seen in water drainage and mixing applications. They are favored for their efficiency and lower maintenance needs. However, they may struggle with thick mud, leading to decreased performance.

Choosing the right pump isn’t always straightforward. Factors such as mud composition, pump capacity, and project requirements must be considered. It’s easy to overlook specific nuances, like pressure ratings and flow rates. A minor miscalculation can impact the whole operation. Regular assessment of pump performance over time also gets neglected. This reflection is crucial for optimizing future projects.

When selecting drilling mud pumps, several critical factors come into play. The pump's capacity is a key aspect. Typically, capacities vary from 500 to 3,000 gallons per minute. For high-volume projects, a pump with a capacity on the upper end of this range is essential. Insufficient capacity may lead to delays and added costs.

Consider the mud characteristics as well. The viscosity and density of the drilling mud can impact pump performance significantly. A study indicated that improper pump selection related to mud properties could decrease efficiency by up to 25%. This highlights the importance of matching pump specifications with the mud's specific characteristics.

Also, evaluate the material quality. Pumps made from high-grade materials can withstand harsh conditions and abrasive slurries. However, these might come at a higher initial cost. Choosing cheaper options can lead to frequent repairs. It’s a trade-off between upfront costs and long-term operational efficiency. Some choices might lead to unforeseen issues during drilling, affecting project timelines and budgets. Reflecting on these factors is crucial for a successful drilling operation.

When selecting drilling mud pumps, evaluating performance and efficiency is crucial. A pump’s capacity often dictates which projects it can handle. Flow rate and pressure are two major factors to consider. You need to ensure the chosen pump delivers the right amount of mud consistently. Sometimes, pumps may work well in theory but fall short in practical applications. Real-world testing can reveal inefficiencies that numbers alone cannot.

Consider the specific type of drilling you will undertake. Different projects may require varying levels of viscosity and flow control. A pump that excels in one scenario might struggle in another. Check if the pump can handle both high and low pressures. This versatility often leads to more efficient operations. However, you might find that even the best pumps experience wear and tear. Regular maintenance is essential to keep them running smoothly.

Efficiency isn’t just about numbers; it’s about how well the pump integrates with your overall project setup. Look for features that enhance operational efficiency. Automated controls can save time and reduce human error. But, these features might increase the initial investment. Weighing the upfront costs against long-term savings is often tricky. Ensure that the pump you choose aligns with your project’s specific needs and budget.

Drilling mud pumps are essential for various projects. Maintaining these pumps is crucial for their longevity and performance. According to a recent industry report, proper maintenance can increase the lifespan of drilling mud pumps by up to 30%. Regular checks and timely repairs can save significant costs in the long run.

One vital tip is to monitor the pump's fluid levels regularly. Low fluid levels can lead to overheating and pump failure. Additionally, using the right type of mud is crucial. The wrong mixture can cause wear and tear on pump components. Scheduled inspections are important. Aim for inspections every three to six months, depending on usage.

Cleaning the pump is another key practice. Dirt and debris can clog the system, hindering efficiency. Routine cleaning can prevent costly breakdowns. Operators should also keep an eye on performance metrics. Sudden drops in pressure can indicate a problem needing immediate attention. Ignoring these signs can lead to bigger issues down the line.

This chart displays the flow rates of different drilling mud pumps, helping you understand which options may be more suitable for your project. It is important to maintain these pumps properly to ensure optimal performance and longevity.