When selecting the right drilling mud pumps for your project, it is essential to consider various factors. Renowned industry expert, John Smith, once stated, "Choosing the right drilling mud pump can determine the efficiency of your entire drilling operation." This highlights the importance of understanding the specific needs of your project.

Drilling mud pumps play a critical role in maintaining the circulation of drilling fluid. They help transport the mud to the surface and keep the drilling process efficient. Choosing the wrong pump can lead to costly delays and operational inefficiencies. Considerations include pump capacity, viscosity of the drilling fluid, and the specific application requirements.

Many projects overlook the complexities involved in selecting drilling mud pumps. It’s easy to assume one size fits all, but that can lead to suboptimal performance. Evaluating your project’s unique needs is key. Pay attention to the pump's durability and maintenance requirements as well. Balancing quality and cost is not always straightforward, but it is crucial for overall success.

Drilling mud pumps play a crucial role in various drilling projects. They circulate the drilling fluid, which helps to cool the drill bit and remove cuttings. Proper circulation maintains the stability of the borehole, preventing collapses. Without an effective pump, the entire drilling operation could face significant delays.

Choosing the right pump is not always straightforward. Factors such as the viscosity of the mud and the depth of the well need careful consideration. A pump that works well in one project may not perform adequately in another. It’s essential to consult experts or conduct thorough research. Sometimes, even small adjustments in pump configuration can lead to better efficiency.

There are different types of pumps based on project needs. Some are designed for higher pressure, while others focus on high flow rates. Assessing the specific demands of your project is vital. Ignoring this aspect may lead to poor performance. Regular evaluations and adjustments are recommended to ensure optimal functionality throughout the project.

Choosing the right drilling mud pumps requires careful consideration of several key factors. One major aspect is the pump's flow rate. According to industry reports, pumps with varying flow rates can significantly impact drilling efficiency. For instance, a flow rate of 200-600 GPM (gallons per minute) is often recommended for medium to large drilling projects. A flow rate that's too low may lead to increased viscosity and ineffective cuttings removal.

Pressure is another critical consideration. Pumps need to maintain a specific pressure range to ensure proper circulation of the drilling fluid. A report from the Society of Petroleum Engineers indicates that optimal pressure settings can enhance drilling performance by up to 30%. However, if the pressure exceeds the safe limits, it may cause equipment failure or decreased operational longevity.

It's also essential to assess the pump's compatibility with various drilling fluids. Different mud properties demand specific pump designs. Using a pump that doesn’t match the fluid characteristics may result in excessive wear or inefficient performance. Regular evaluations and adaptations to equipment and fluid types can avoid costly setbacks. Addressing these factors thoughtfully can lead to more successful drilling operations.

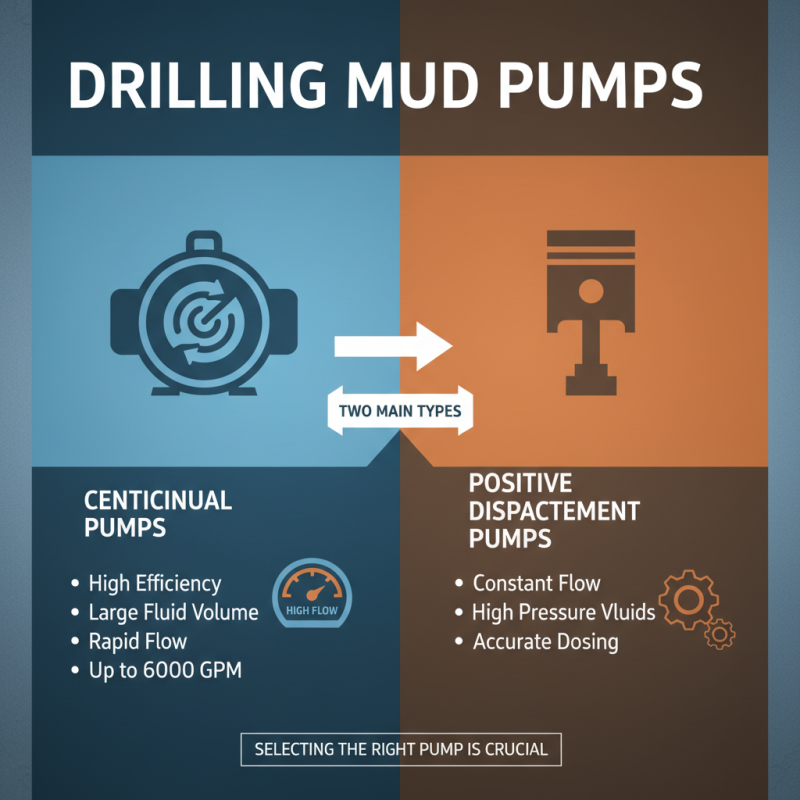

When selecting drilling mud pumps, understanding the types available is crucial. Two main categories exist: centrifugal and positive displacement pumps. Centrifugal pumps are widely used due to their efficiency. They handle large volumes of fluid quickly, making them suitable for high-flow applications. According to industry reports, these pumps can achieve flow rates up to 6,000 gallons per minute.

Positive displacement pumps operate differently. They provide consistent pressure and are better for high-viscosity fluids. Their flow rate is independent of pressure, which can be advantageous in certain drilling conditions. Reports indicate that these pumps often maintain operational efficiency even in difficult environments. However, they may require more maintenance than centrifugal pumps.

When choosing a pump, consider the fluid's properties. Density, viscosity, and temperature all impact performance. For instance, a thicker mud requires a pump with robust capabilities. Additionally, not all pumps operate well with abrasive materials, potentially leading to increased wear and tear. Conducting thorough research and testing different configurations can mitigate risks. Balancing efficiency and longevity can be challenging, but critical for project success.

Assessing project requirements is crucial for optimal pump performance. In drilling operations, pump selection greatly affects efficiency. Key factors include the type of drilling, fluid viscosity, and required flow rate. Reports indicate that improper pump choices can lead to energy losses of over 30%. Understanding these requirements is vital.

Consider the well depth and geological formations. Different setups may require unique pumping solutions. For instance, mud with high density demands more robust pumps. In many cases, high-pressure applications exceed normal specifications. This can create challenges for pump longevity and performance.

A study by the Society of Petroleum Engineers highlighted that nearly 25% of projects face delays due to inadequate pump specifications. Reflecting on these data points can guide better decision-making. Assessing specific needs ensures the chosen pump will function effectively, reducing downtime and enhancing productivity.

When working with drilling mud pumps, maintenance and support are critical. Regular servicing ensures the pumps operate efficiently. Statistics show that proper maintenance can extend pump life by up to 30%. Inconsistent maintenance schedules can lead to costly downtime. This influences project timelines and budgets significantly.

Operators need to monitor wear and tear regularly. For instance, seals and bearings are common failure points. These components should be checked at least every 500 hours of operation. Neglecting these checks might result in unexpected breakdowns. Moreover, a feedback loop involving operators can enhance performance. Gathering insights from the field helps in identifying recurrent issues.

Support from technical teams is invaluable. Assistance in troubleshooting can save hours of lost productivity. Companies should prioritize training for their staff. Educated technicians are more effective in spotting problems early. However, many teams overlook the importance of continuous training. This oversight can lead to operational inefficiencies. Keeping a close eye on pump performance metrics is essential to maintain productivity and quality.