Choosing the right Oil Drilling Equipment for your project is crucial. The equipment you select will influence efficiency, safety, and overall success. Various factors come into play when making this decision.

Start by assessing project specifics. Consider the depth and location of the drilling site. Different terrains require different machinery. Next, think about the project budget. Quality equipment can be expensive, but investing wisely pays off. Avoid cutting corners that could lead to problems later.

Additionally, reflect on equipment maintenance and support. Will your team handle repairs? Are spare parts readily available? Sometimes, a cheaper option turns expensive when maintenance is considered. The challenge is to balance cost, quality, and capabilities of the Oil Drilling Equipment. Making informed choices is not always straightforward. Be prepared to adjust your options as new information arises.

Choosing the right oil drilling equipment for your project is crucial. Several factors impact your selection. These include the project's scale, drilling depth, and environmental considerations. A thorough assessment of these factors ensures you choose suitable equipment.

One key factor to consider is the drilling method. Different methods may require unique equipment types. For instance, rotary drilling needs a different set compared to directional drilling. Evaluate your project’s requirements carefully.

Tips: Always consult with experienced professionals. They can provide insights that save time and resources. It's also vital to stay within your budget. A more expensive option may not always be the best choice. Remember, equipment reliability is paramount. Ensure it meets safety standards and performs efficiently.

Another important element is maintenance. Some equipment is easier to maintain than others. This could affect downtime during your project. Think about the availability of spare parts. A lack of supplies can hinder your operations significantly. Balancing initial costs with long-term reliability is essential.

When selecting oil drilling equipment, it’s essential to understand the main types available. Drill rigs are commonly used for exploration and production. These come in various sizes, fitting different project scales. You might consider mobile rigs for flexibility. Their ability to move quickly saves time on-site.

Another category is mud pumps. These pumps circulate drilling fluid, which cools the drill bit. A reliable mud pump can prevent overheating. Also, look for shakers that separate solids from fluids. They play a critical role in maintaining fluid quality. Finding the right equipment can feel overwhelming, especially with so many options.

Don’t overlook rotary table rigs. They are essential for the drilling process. Yet, not every project requires them. Sometimes, a simpler approach may suffice. Assess your project's specific needs. It’s fine to reconsider your initial choices. Staying informed can enhance decision-making. Remember, the goal is efficiency and safety.

When choosing oil drilling equipment, performance metrics are crucial. Evaluating efficiency means looking at how well the equipment will perform in the field. Factors like speed, power consumption, and maintenance needs must be examined. Metrics can reveal the real capabilities and limitations of the equipment.

Compatibility is another key aspect. Each project has specific requirements that equipment must meet. Analyzing compatibility can help avoid costly downtime. Sometimes, what seems perfect on paper does not translate to actual performance. Testing equipment under real conditions is vital. If it doesn't fit the environment well, it can lead to frustration.

Decisions should not be made hastily. Gathering feedback from team members can provide essential insights. Reflecting on past experiences can help avoid repeating mistakes. Every project offers lessons learned, and integrating these lessons will enhance future efficiency and compatibility.

| Equipment Type | Efficiency Rating | Compatibility | Maintenance Requirements | Cost Estimate |

|---|---|---|---|---|

| Rotary Drills | High | All terrains | Moderate | $500,000 - $1,000,000 |

| Top Drive Systems | Very High | Specific rigs | Low | $300,000 - $600,000 |

| Mud Pumps | Moderate | All types | High | $100,000 - $250,000 |

| Casing Equipment | High | Various | Moderate | $250,000 - $500,000 |

| Drilling Rigs | High | Standard | High | $2,000,000 - $5,000,000 |

Budgeting for oil drilling equipment is crucial. You must account for both initial costs and ongoing maintenance. Upfront costs can vary significantly based on the type of equipment. For instance, drilling rigs may range from hundreds of thousands to millions of dollars. Don't overlook transport expenses, site preparations, and additional tools.

Maintenance is often neglected in initial budgets. Regular upkeep can prevent costly breakdowns. Developing a maintenance schedule early on can help. Consider setting aside 10-15% of your initial investment for ongoing repairs and servicing. This often requires diligent tracking to manage expenses correctly.

Additionally, unexpected costs can arise. Price fluctuations in materials may impact your budget. Always prepare for contingencies. It’s wise to consult with industry experts for realistic estimates. Reflecting on past projects can provide valuable insights. Each project teaches lessons about what to prioritize, helping refine future budgeting efforts.

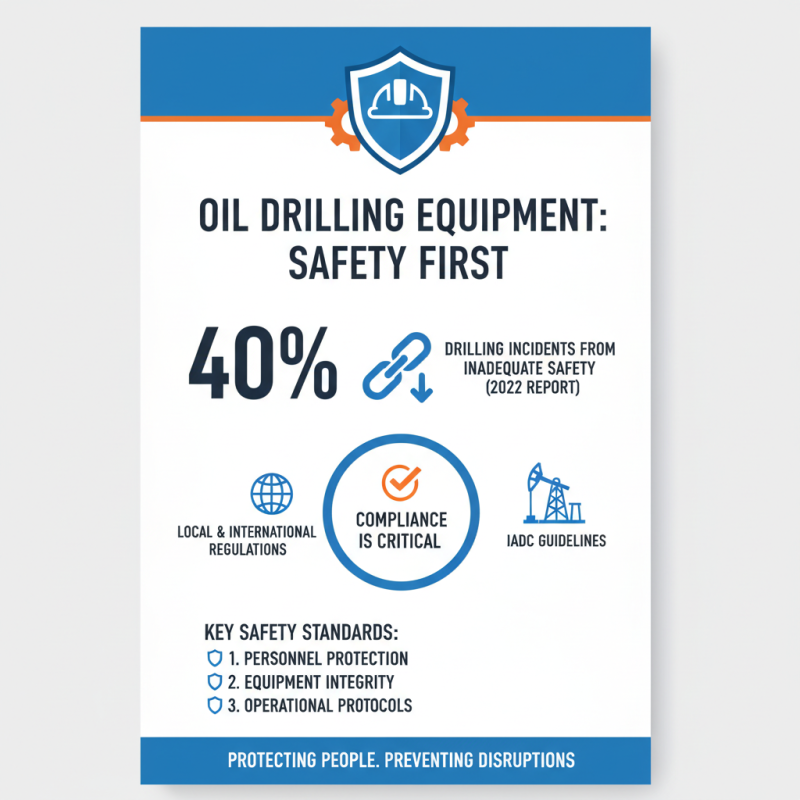

When selecting oil drilling equipment, safety standards are paramount. The International Association of Drilling Contractors (IADC) emphasizes that compliance with local and international safety regulations is critical. In 2022, industry reports highlighted that approximately 40% of drilling incidents stem from inadequate safety measures. These incidents not only disrupt operations but also pose risks to personnel.

Effective risk management strategies are vital. Detailed hazard assessments can identify potential issues before they arise. Training programs increase awareness of safety protocols among workers. However, many teams still overlook routine safety drills. This gap can lead to severe consequences in case of emergencies. A 2021 study revealed that companies with regular training reported 30% fewer accidents.

Investing in modern safety equipment is necessary, yet not sufficient. For instance, personal protective equipment (PPE) should always meet the latest industry standards. Yet, a survey found that 25% of survey respondents admitted to not using proper PPE consistently. This inconsistency raises alarms about the frequently overlooked aspects of drilling safety. Compliance can often feel like a check-box exercise, but real awareness is vital for a safe working environment.