Selecting the right Oil Drilling Equipment is crucial for any drilling project. The equipment affects efficiency, safety, and overall costs. Proper choices can enhance productivity and minimize unnecessary expenses.

Consider the specific demands of your project. Different drilling sites require various tools, from rigs to safety gear. Assess factors like soil type, depth, and environment. Each element can impact the effectiveness of your chosen equipment.

Thinking about your budget is important too. High-quality tools may cost more upfront but lead to savings in the long run. A thorough assessment of how you will use the equipment is vital. Reflecting on past experiences can guide your decision-making. Ultimately, make informed choices to achieve project success with the appropriate Oil Drilling Equipment.

When selecting oil drilling equipment, understanding the variety can significantly impact the project's success. The primary types include rotary rigs, drilling rigs, and offshore equipment. Each plays a unique role in the drilling process. For instance, rotary rigs are widely used for their efficiency in extracting oil from land wells. According to a report by the International Energy Agency, these rigs can increase production rates by up to 25%.

Tips: Always assess the geological conditions before choosing equipment.

Drilling rigs, another crucial type, vary in size and capability. Some are designed for shallow wells, while others can reach depths exceeding 30,000 feet. This variation is essential depending on your target oil reservoir. Offshore equipment is specialized for marine environments. It ensures safety and performance under challenging conditions. In 2023, global offshore drilling investments were projected to reach over $100 billion, reflecting its growing importance.

Tips: Prioritize the most suitable equipment for your operational depth.

However, not all projects require the latest technology. Costs are an essential factor. Sometimes, older but reliable equipment may be the best choice. Make informed decisions and avoid rushing into purchasing the most advanced models. Consider the long-term implications on your budget and operations. Choose wisely to balance technology and affordability.

Choosing the right oil drilling equipment starts with clearly assessing your project's requirements. Different projects demand different tools. Consider the depth of the drilling site. Is it shallow or deep? Shallow drilling might need lighter equipment, while deep drilling requires more robust machines.

Take the time to evaluate geological conditions. The type of soil or rock can significantly influence your choice. Hard rock formations may necessitate more advanced drilling rigs. Think about the environment too. Is the site remote or easily accessible? Equipment transport may be a bigger factor than expected.

Budget constraints also play a crucial role. Sometimes, opting for lower-cost options can lead to setbacks. Equipment that fails or requires frequent repairs can be costly in the long run. Reflect on past projects as well. What worked well? What didn't? Gathering this information drives better decision-making. Ultimately, the right equipment aligns with your project's unique needs, leading to more successful outcomes.

When selecting oil drilling equipment, performance and efficiency are crucial factors. Evaluating how each piece performs in varied conditions can save time and money. Understand that not all equipment is suited for every project. The soil type, depth of drilling, and environmental conditions all influence equipment effectiveness. Some drills may underperform in rocky terrain, leading to additional costs.

Efficiency standards also play a significant role. Equipment with high efficiency reduces fuel consumption and operational time. However, high efficiency may come with higher initial costs. This creates a dilemma for project managers. Choosing equipment should involve a balance between upfront investment and long-term savings.

Consider reviewing past project metrics as part of your evaluation. Real-world data reveals how equipment performed under various scenarios. Look for distinct patterns; notice where certain machines failed to meet expectations. Questions remain, though. Did the design contribute to inefficiency? Were operator skills adequate? Reflecting on these aspects ensures better choices in future projects.

| Equipment Type | Performance Standard | Efficiency Rating (%) | Max Depth (m) | Cost Estimate ($) |

|---|---|---|---|---|

| Rotary Drilling Rig | API 7K | 85 | 3000 | 1,500,000 |

| Directional Drilling System | ISO 9001 | 90 | 4000 | 2,000,000 |

| Exploration Drill | BS 8800 | 78 | 1500 | 850,000 |

| Workover Rig | API 4F | 83 | 2500 | 1,200,000 |

| Drilling Barge | DNV GL | 88 | 2000 | 2,500,000 |

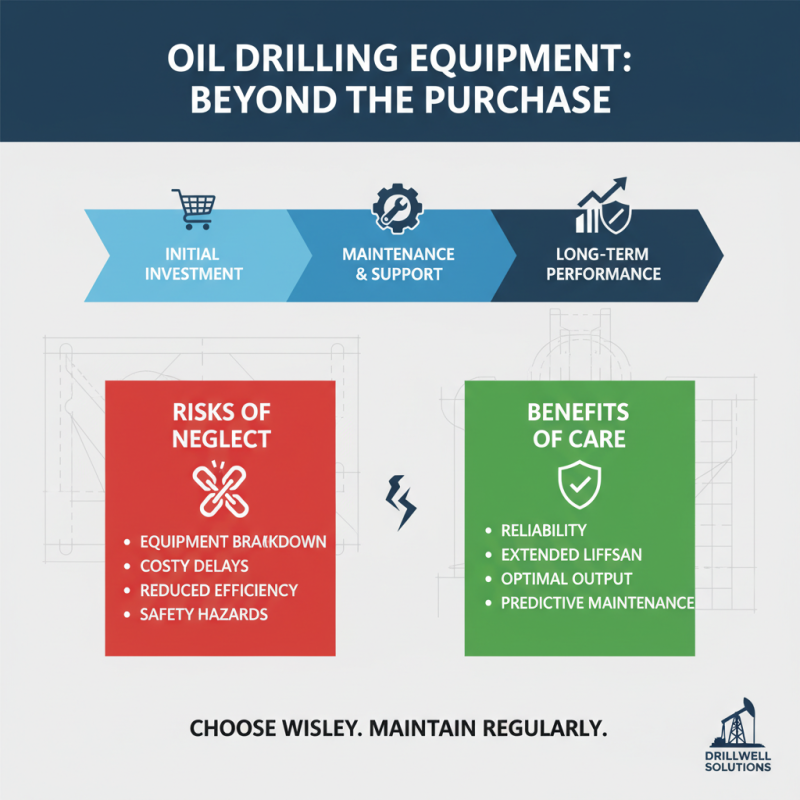

Maintenance and support services are vital when choosing oil drilling equipment. It's not just about the initial purchase. Consider the long-term performance and reliability of your equipment. If the equipment breaks down, it can lead to costly delays. Regular maintenance can prevent these situations.

Look for suppliers that offer comprehensive service packages. This should include routine inspections and repair services. Ask about their response time for emergencies. A quick response can make a big difference in maintaining productivity. Evaluate their technicians’ qualifications and experience. Sometimes, the best equipment can fail due to poor maintenance support.

Don’t overlook training for your team. Proper training can reduce wear and tear on the equipment. Well-trained operators are more likely to identify issues early. This proactive approach minimizes downtime and extends the lifespan of the machinery. Reflect on your specific needs and the complexity of operations. Tailored maintenance plans can ultimately save you time and money.

When it comes to budgeting for oil drilling equipment, companies must weigh their options carefully. Equipment costs can vary greatly, influenced by factors like type, size, and technology. A recent study showed that drilling rigs can cost anywhere from $1 million to over $30 million. This wide range indicates the importance of matching equipment capabilities to project requirements.

Cost analysis should also include operational expenses. Between maintenance, fuel, and manpower, operational costs could add up to 50% of the total project budget. Failing to account for these can lead to overruns. In fact, industry reports suggest that improper budgeting often leads to project delays, costing companies thousands daily in lost revenue.

Investing wisely involves reflecting on future needs. For instance, investing in advanced drilling technology may offer better efficiency. Yet, if the project is short-term, that investment might not pay off. Companies should regularly assess their choices. Avoiding costly mistakes in equipment procurement is essential for maintaining profitability in today’s competitive landscape.