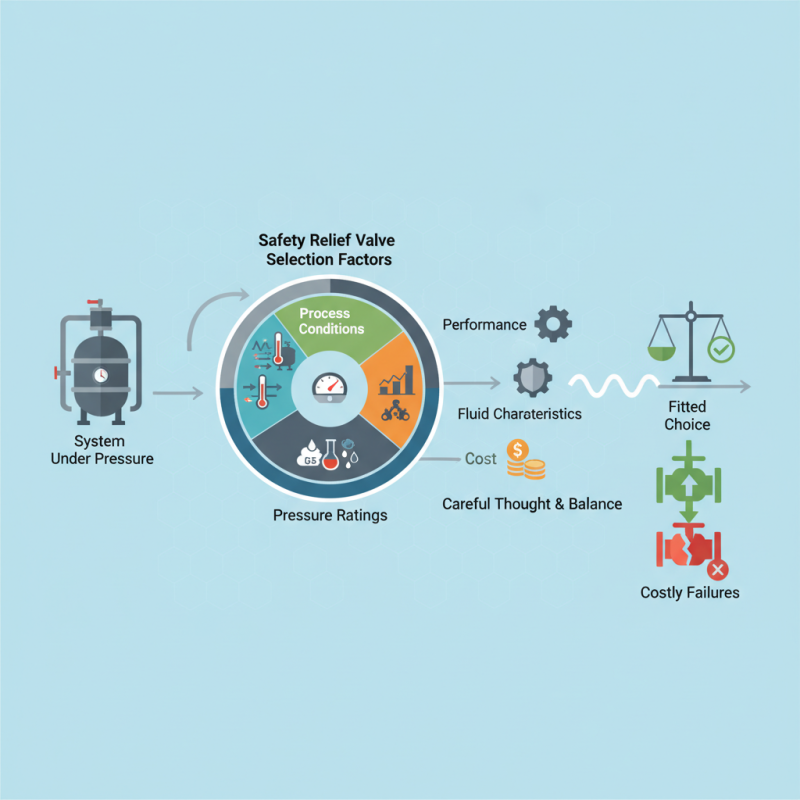

Choosing the right Safety Relief Valve can be a daunting task. Various factors influence your decision. Understanding these factors is crucial for effective selection.

Safety Relief Valves are essential in preventing system overpressure. They protect equipment and ensure safety. Yet, many people overlook their specific requirements. Some may assume one valve fits all, which is a risky mindset. Your process conditions, pressure ratings, and fluid characteristics matter greatly.

It is important to assess your unique situation. Misjudgments can lead to costly failures. Don't rush—take your time to research. Balancing performance, reliability, and cost can require careful thought. A thorough evaluation will lead you to a fitting choice, but beware of the temptation to compromise.

Safety relief valves play a crucial role in protecting equipment and systems from excessive pressure. They do this by releasing excess pressure automatically when it reaches a predetermined level. Understanding how these valves operate is essential for anyone involved in system design or maintenance.

When selecting a safety relief valve, consider the application. Different environments may require different specifications. For example, valves that operate in high-temperature applications must be designed to handle such stress effectively. The selection process can often be complex. Many fail to account for factors like fluid type and pressure variations.

Incorrect choices can lead to serious failures. Regular testing and maintenance of the valves help ensure optimal performance. Always reflect on past incidents and consider improvements. Safety relief valves are essential, but they need to be chosen wisely. A valve that operates perfectly in one situation might fail in another. Each application demands careful thought.

Safety relief valves play a crucial role in various industries. Choosing the right type ensures optimal performance and safety. There are several categories of safety relief valves. Each serves specific functions tailored to different applications.

For example, spring-loaded valves are commonly used in pressurized systems. They maintain a set pressure point and release excess pressure as needed. This type excels in environments like chemical processing and oil refining. According to industry reports, around 60% of facilities in these sectors rely on spring-loaded valves for their reliability.

Another type is the pilot-operated relief valve. These valves provide high accuracy in controlling pressure levels. They are often utilized in larger operations, such as power plants. However, they require careful maintenance to prevent failures. A study revealed that about 15% of valve malfunctions stem from improper maintenance. Understanding these types and their unique applications is essential for effective pressure management.

| Type of Valve | Application | Pressure Range (psi) | Material | Installation Location |

|---|---|---|---|---|

| Spring-Loaded Safety Relief Valve | Steam, Gas | 30 - 300 | Stainless Steel | Industrial process equipment |

| Pilot-Operated Safety Relief Valve | Liquid | 100 - 1500 | Carbon Steel | Refineries, chemical plants |

| Balanced Bellows Safety Relief Valve | High-Pressure Gas | 1000 - 3000 | Hastelloy | Oil and gas industry |

| Thermal Relief Valve | Hydraulic Systems | 250 - 1000 | Bronze | Compact circuits |

When selecting a safety relief valve, key factors must be evaluated. Pressure ratings are crucial. Ensure it matches your system's maximum allowable pressure. Incorrect ratings can lead to severe failures. Materials also matter. Choose valves made from durable materials suitable for your application. Corrosion resistance might be necessary, depending on the environment.

Another aspect is valve size. It must fit your system's piping layout. An oversized valve can lead to erratic performance. Too small, and it won’t relieve enough pressure. Don’t forget about the inlet and outlet connections. Proper compatibility ensures smooth installation and operation.

Lastly, consider the environment. Is it gas or liquid? High temperature or low? Ensure your choice conforms to these needs. A mismatched valve could fail under stress. Take time to consult experts if necessary. Mistakes in selection can lead to costly consequences. Take every detail seriously.

Choosing the right safety relief valve involves careful consideration of sizing and pressure ratings. Proper sizing ensures that the valve can handle the required flow rates effectively. According to industry reports, approximately 70% of safety relief valve failures result from incorrect sizing. This emphasizes the importance of thorough calculations.

When determining pressure ratings, it is vital to assess the system's pressure conditions. Many engineers recommend that the relief valve’s set pressure should not exceed the system's maximum allowable pressure. Reports indicate that valves set too high can lead to catastrophic failures. On the other hand, inadequate pressure ratings can lead to premature tripping, which disrupts operations.

In practice, many technicians overlook the effects of temperature on valve performance. High temperatures can weaken materials, affecting reliability. The American Society of Mechanical Engineers (ASME) suggests that regular inspections mitigate risks, yet only 55% of facilities conduct them consistently. Careful attention to these factors is critical for safe and efficient operations. Ensuring that the safety relief valve is up to standard requires constant vigilance and willingness to adapt based on operational data.

When it comes to installing safety relief valves, precision and care are crucial. Choose the correct valve size for your application. A valve that is too small may not relieve pressure adequately. Conversely, an oversized valve can lead to unnecessary wear. Ensure the installation area is free from debris. This helps maintain the valve’s effectiveness.

**Tips:** Always read the manufacturer's guidelines before installation. Understand the pressure requirements and fluid characteristics. Recognizing these factors can prevent potential mishaps.

Maintenance is equally significant. Regular inspections are essential. Check for signs of corrosion or wear. These issues can compromise the valve's function. If a valve has not been tested in a while, a functional test is necessary. This not only ensures safety but enhances reliability.

**Tips:** Develop a maintenance schedule tailored to your system. Note any changes in performance. Keep a record of all maintenance activities. These steps bolster safety and extend the valve's lifespan.