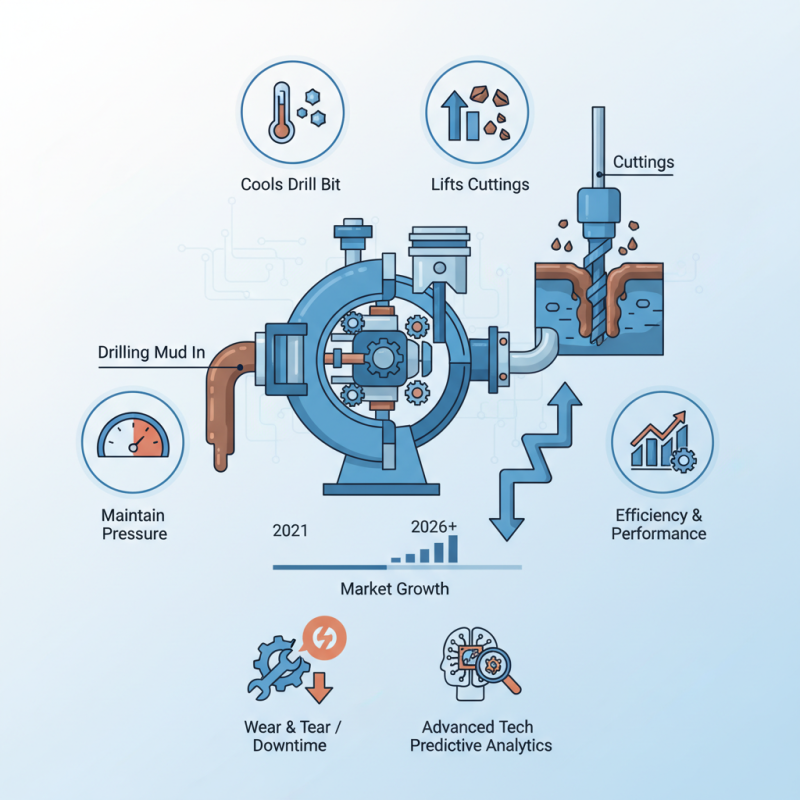

Drilling Mud Pumps play a crucial role in the oil and gas industry. These pumps circulate drilling fluid, also known as mud, throughout the drilling process. This fluid cools the drill bit, lifts cuttings, and helps maintain pressure. Industry reports suggest that the global drilling mud market reached USD 6.83 billion in 2021, with an expected growth rate of over 5% annually. The efficiency of Drilling Mud Pumps significantly impacts this market.

Understanding how these pumps operate is essential for optimizing drilling operations. A pump must handle the varying viscosity of different mud types. The challenges faced, such as wear and tear and maintenance, can affect performance. A report by the International Association of Drilling Contractors indicates that downtime due to pump failure can be costly. Understanding potential failure points and necessary maintenance can improve reliability and efficiency.

Investing in advanced Drilling Mud Pumps that feature automation and predictive analytics can enhance drilling performance. However, companies sometimes overlook these enhancements, focusing on cost-cutting instead. This approach can lead to long-term inefficiencies. Recognizing the importance of these pumps is essential for operational success in a competitive market.

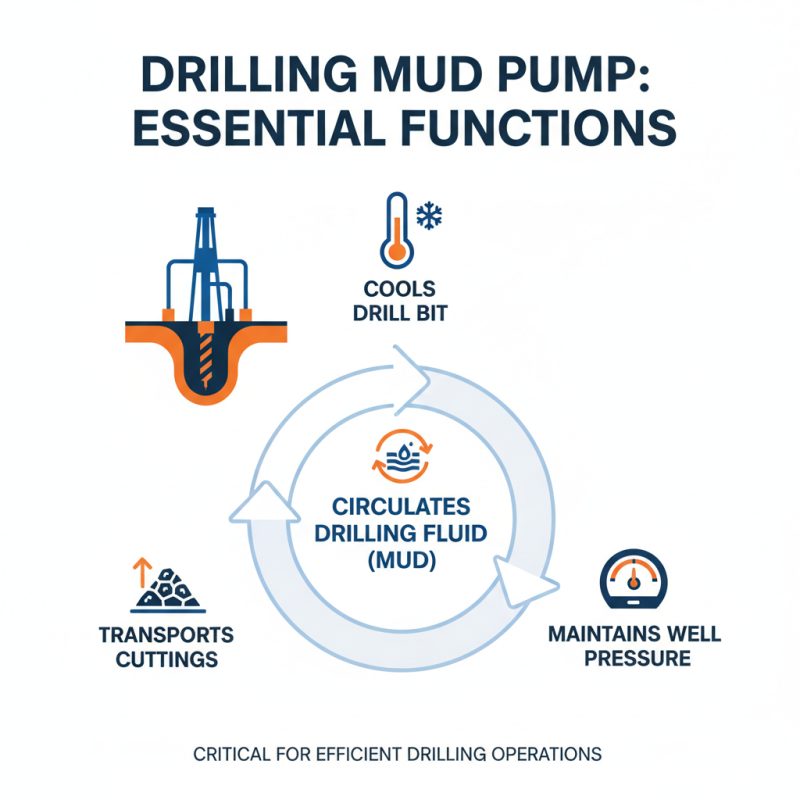

A drilling mud pump is essential in the drilling industry. It is designed to circulate drilling fluid, also known as mud, during the drilling process. This fluid serves multiple purposes, such as cooling the drill bit, transporting cuttings, and maintaining pressure.

The pump takes the mud from the mud pit and pushes it through the drill string and back out through the annulus. This movement helps in keeping the drilling area clean. There are different types of pumps, such as centrifugal and positive displacement pumps. Each type has its advantages and disadvantages depending on the drilling environment.

Drilling mud pumps are not without challenges. They can face issues like wear and tear due to abrasive materials in the mud. Regular maintenance is crucial to keep them functioning properly. Operators must also ensure the correct type of mud is used to match the pump’s specifications. Balancing performance with efficiency can be tricky and requires ongoing attention.

A drilling mud pump is vital in the drilling industry. It circulates drilling fluid, known as mud. This fluid lubricates the drill bit and carries rock cuttings to the surface. Understanding its key components is essential for effective operation.

The pump consists of several main parts. The piston is crucial. It generates the pressure needed to pump the mud. The cylinder houses the piston, ensuring a tight seal. The inlet and outlet valves regulate the flow of the mud. If these components fail, it disrupts the entire drilling process. Regular maintenance is necessary to prevent such issues.

Another important part is the motor. It powers the pump, enabling it to operate efficiently. Different types of motors may be used, and choosing the right one is important. The power requirement often varies based on the project. Occasionally, operators might overlook the motor’s calibration. This oversight can lead to inefficient performance. Attention to detail in these components is vital for smooth drilling operations.

| Component | Function | Materials Used | Typical Applications |

|---|---|---|---|

| Pump Body | Houses the internal components and withstands pressure. | Carbon Steel, Stainless Steel | Oil and Gas Drilling |

| Piston | Creates suction and discharge to move drilling mud. | High-grade Alloy, Rubber | Well Drilling, Geothermal Applications |

| Valves | Regulate the flow of fluid within the pump. | Brass, Stainless Steel | Drilling Operations, Fluid Transfer |

| Drive Mechanism | Converts mechanical energy into hydraulic energy. | Electric Motor, Diesel Engine | Drilling Rigs, Construction Sites |

| Suction and Discharge Ports | Intake and output points for the drilling fluid. | Plastic, Steel | Mud Circulation Systems |

Drilling mud pumps play a crucial role in drilling operations. They circulate drilling fluid, known as mud, to remove cuttings from the wellbore. This fluid cools the drill bit and stabilizes the borehole. By maintaining pressure, it prevents collapse and keeps unwanted fluids out.

The functioning process of these pumps is quite fascinating. Mud is drawn from a storage tank through a suction line. The pump uses a mechanical mechanism to push the mud down the drill pipe. High pressure is essential to ensure efficient circulation. Without this pressure, the fluid would not reach the drill bit as needed.

In practice, maintaining the right viscosity and flow rate of the drilling mud can be challenging. If the mud is too thick, it may not flow properly. If it’s too thin, it could compromise the well's integrity. Operators must constantly monitor these properties. It’s an ongoing process of trial and error to achieve optimal performance.

Drilling mud pumps play a vital role in the drilling process. There are different types of pumps used in the industry. Each has its own specific applications and advantages.

Positive displacement pumps are common for their reliability. They create a consistent flow of drilling fluids. Their design allows them to handle varying viscosities. However, they can be prone to wear over time, necessitating careful maintenance.

Centrifugal pumps are another option. These pumps excel in higher flow rates but are less effective with thicker fluids. They are often used in surface applications. Still, their efficiency drops with increased viscosity, which is a limitation to consider. Each type has unique strengths and weaknesses, influencing the choice for particular drilling projects. It’s essential to evaluate factors like fluid properties and operational conditions to select the right pump.

Maintaining a drilling mud pump is crucial for reliable performance. Regular checks help identify issues early. Start with inspecting the pump's pressure gauge. A sudden pressure drop may indicate a leak. Monitor the pump for unusual noises. Grinding sounds could signal internal damage, requiring immediate attention.

Tips: Keep a log of all maintenance activities. Documenting each task helps track issues over time. It also aids in troubleshooting.

Look closely at the mud's viscosity. If it's too thick, it can strain the pump. Pump failure might stem from inadequate fluid properties. Consider adjusting the formulation if necessary. Watch for signs of wear on the internal components. Corrosion or excessive wear may compromise the pump's efficiency.

Tips: Regularly replace worn parts. It can save money in the long run. Delayed maintenance often leads to more severe problems.

This chart shows the performance of drilling mud pumps based on flow rate and pressure settings. It highlights the efficiency of various pumps in different operational ranges.