When it comes to lifting and material handling, selecting the right equipment is crucial. Rope Block Sheaves play a significant role in optimizing performance and safety. Industry expert John Harris, a seasoned engineer with over 20 years of experience, once stated, “The right Rope Block Sheaves can make or break your lifting operation.” His words highlight the importance of understanding these components.

These sheaves come in various designs and materials, each suited for specific applications. Whether you're in construction, manufacturing, or shipping, you need reliable tools. The selection process may seem overwhelming. Not all Rope Block Sheaves are created equal. Factors such as load capacity, durability, and compatibility must be considered carefully.

Rope Block Sheaves are not just components; they are the backbone of lifting systems. You may find that an overlooked detail leads to inefficiency. This article explores the top 10 essential Rope Block Sheaves tailored for your lifting needs. Each option is analyzed for its strengths and weaknesses, encouraging reflection on what works best for your unique requirements.

When selecting rope block sheaves, several essential features must be

considered for optimal performance.

Load capacity is crucial. According to industry reports, sheaves with a higher working

load limit significantly improve safety and efficiency. A minimum working load limit of

2,000 pounds is recommended for heavy lifting tasks.

This ensures durability and can handle unexpected loads.

Material choice is another key factor. Aluminum and composite materials have gained

popularity due to their lightweight properties. Surveys indicate that 30%

of users prefer aluminum for its strength-to-weight ratio. However, users should be wary of

corrosion resistance. A sheave without proper treatment can

degrade over time, leading to failures in high-stress environments.

Finally, the design of the sheave groove cannot be overlooked. The groove

should match the rope diameter to reduce wear. A poorly matched groove can lead to

premature rope fraying. Users often overlook this detail, which could be detrimental in

the long run. Proper alignment of the rope in the sheave is essential for efficiency.

Minor misalignments can cause increased friction, leading to operational issues.

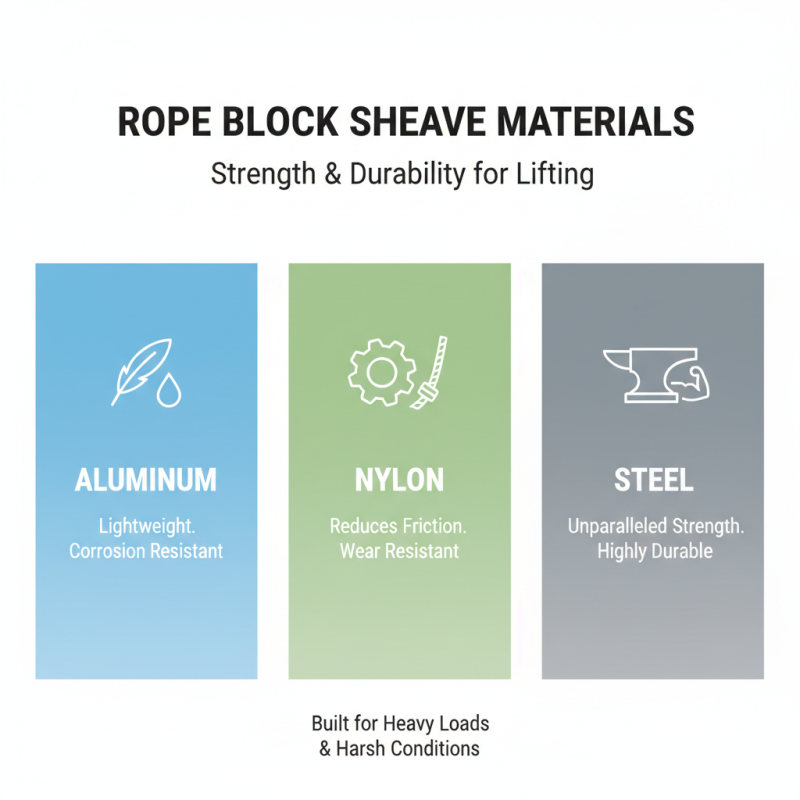

When it comes to lifting, the choice of rope block sheaves plays a crucial role. Durable materials ensure that sheaves can withstand heavy loads and harsh conditions. Commonly used materials include aluminum, nylon, and steel. Each has its strengths. Aluminum is lightweight and resistant to corrosion. Steel, on the other hand, offers unparalleled strength and durability.

Nylon sheaves are also popular for their flexibility and shock absorption. They suit various lifting needs. However, over time, nylon can wear down if not monitored closely. Consider environmental factors. For example, exposure to UV light can degrade nylon over time. Regular inspection is essential to ensure safety.

Tips: Always choose materials based on the lifting environment. Assess the load requirements before purchasing. Consider replacing sheaves after a specific period, even if they appear fine. Wear and tear can be deceptive. Prioritize safety in every lifting operation.

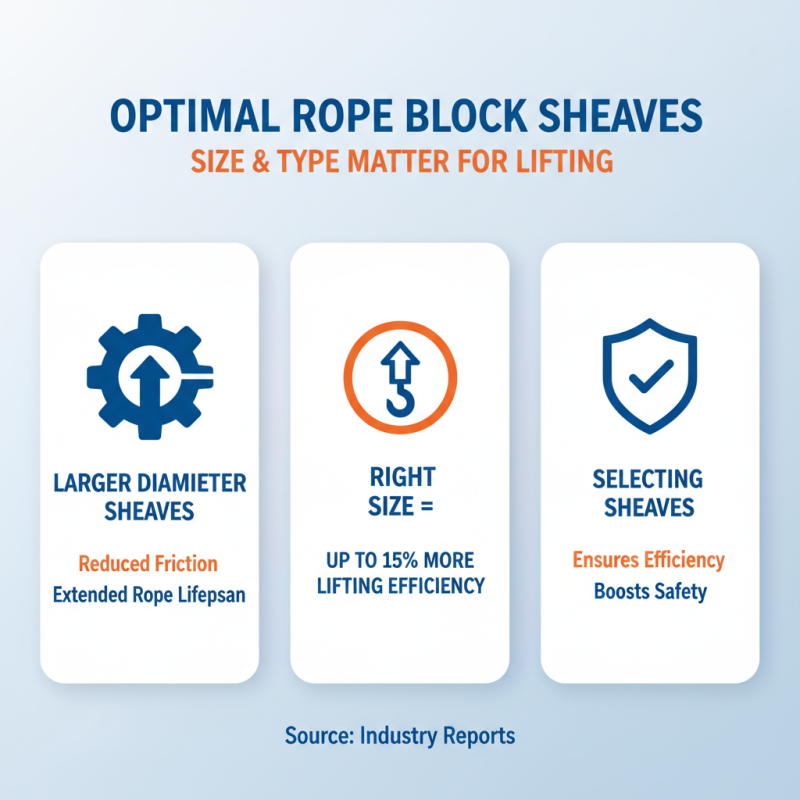

When selecting rope block sheaves, size and type matter significantly. Different lifting tasks require specific sheaves to ensure efficiency and safety. For instance, larger diameter sheaves reduce friction, which can extend rope lifespan. Industry reports suggest that using the right size can improve lifting efficiency by up to 15%.

Rope block sheaves are available in various materials. The choice between aluminum or steel affects weight and capacity. Aluminum sheaves, while lighter, may not handle heavy loads as well as steel. According to recent studies, approximately 25% of lifting accidents are linked to the improper selection of lifting gear, including sheaves. Evaluating the workload and environment is crucial for optimal performance.

Different applications may demand specialized designs. Sheaves with wide grooves are ideal for synthetic ropes, minimizing wear. However, they are not universally suitable. Some ropes may perform poorly with this design. Monitoring and adapting to your specific needs is vital. Neglecting the unique requirements can lead to inefficiencies or failures in lifting operations.

When it comes to lifting heavy loads, selecting the right rope block sheaves is crucial. These components play a vital role in guiding and managing your lifting systems. Popular brands in the industry focus on durability and reliability. According to a recent industry report, over 70% of users prefer sheaves made from high-quality materials that resist wear and tear.

Manufacturers are increasingly adopting advanced designs that cater to various loads. This trend is reflected in the growing market demand for lightweight yet strong solutions. The right sheave can handle different rope sizes, allowing for versatility in operations. Always keep an eye out for specifications like weight limits and material composition.

Tips: Regularly inspect your sheaves for signs of wear. Small cracks can lead to significant issues. Ensure you follow the weight limits specified to maintain safety and efficiency. Don't neglect the importance of routine maintenance; this can prolong the life of your equipment and improve performance.

Choosing the right rope block sheaves may feel overwhelming. However, understanding the essential features helps. Many users overlook the advantages of adjustable sheaves. These can adapt to various applications, making them ideal for diverse work environments. Being aware of your precise lifting needs is key to making informed decisions.

Maintaining rope block sheaves is crucial for their longevity. Proper care can significantly extend their lifespan. According to industry reports, regular maintenance can increase operational efficiency by up to 30%. This means fewer replacements and more savings in the long run.

Check for wear and tear frequently. Inspect the sheave grooves for signs of abrasion or damage. Minor issues can escalate if ignored. Lubrication is often overlooked. Using the right grease prevents corrosion and reduces friction, which can affect lifting capacity.

Cleaning is another essential step. Dirt and debris build up over time. Use a soft brush to keep the sheaves clean. Neglecting this can contribute to premature failure. In fact, studies indicate that regular cleaning practices improve the durability of rope block sheaves by as much as 25%. It's evident that paying attention to these details can make a big difference.