In the realm of lifting solutions, the significance of "Rope Block Sheaves" cannot be overstated. These crucial components facilitate the effective transfer of load and play an essential role in various lifting applications, from construction sites to industrial settings. According to renowned industry expert Dr. John Lawson, “The efficiency of a lifting system is largely determined by the quality and design of its Rope Block Sheaves.” His insights highlight the necessity of incorporating high-performance sheaves to enhance overall operational efficiency and safety.

As we delve into the top guide for Rope Block Sheaves, it is imperative to understand their design intricacies and how they contribute to lifting mechanisms. The right selection of sheaves not only maximizes load distribution but also minimizes wear and tear, ensuring longevity and reliability in demanding environments. This guide will explore the various types of Rope Block Sheaves, their applications, and best practices for selecting and maintaining these vital components, ultimately leading to improved productivity and safety in lifting operations.

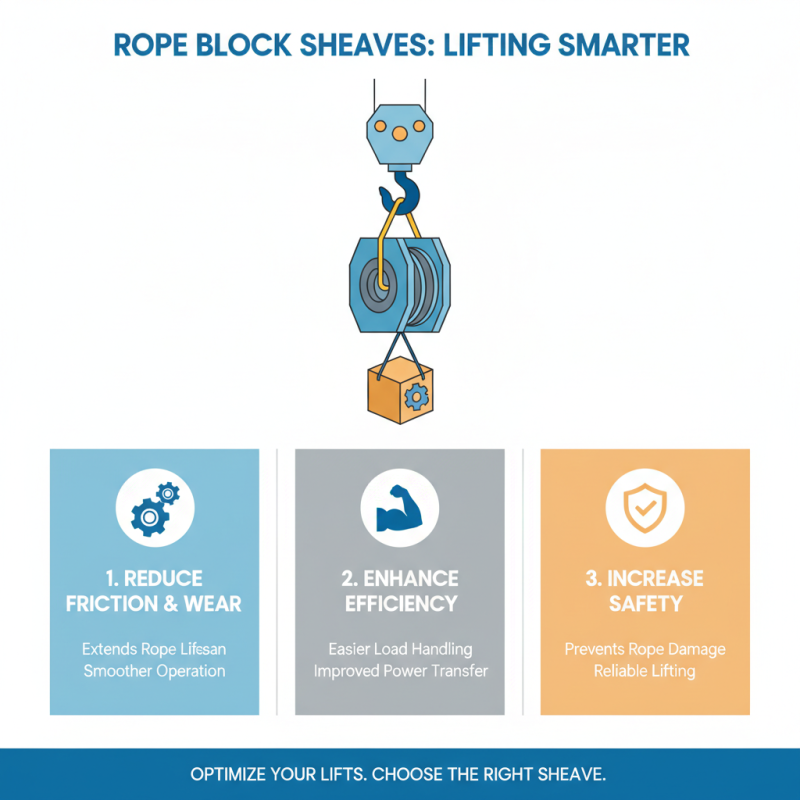

Rope block sheaves play a crucial role in lifting operations, acting as integral components that guide and manage the ropes used in hoisting heavy loads. Understanding their function and importance can significantly enhance the safety and efficiency of lifting tasks. Sheaves are designed to reduce friction and wear on ropes, which prolongs their lifespan and ensures smoother operation. The right sheave can make a noticeable difference in load handling, making it essential for users to select sheaves that complement their specific lifting needs.

When it comes to selecting the appropriate rope block sheave, there are several key factors to consider. The material, size, and design of the sheave must align with the type of load being lifted and the environment in which the lifting takes place. For instance, using sheaves made from durable materials not only prevents premature wear but also enhances performance under heavy loads.

**Tips**: Always inspect your sheaves regularly for signs of wear or damage, and replace them when necessary to maintain optimal safety standards. Additionally, ensure that the rope and sheave sizes match perfectly to avoid slippage or excessive friction, which can lead to accidents. Lastly, be mindful of the sheave's orientation and installation to maximize efficiency and minimize strain during lifting operations.

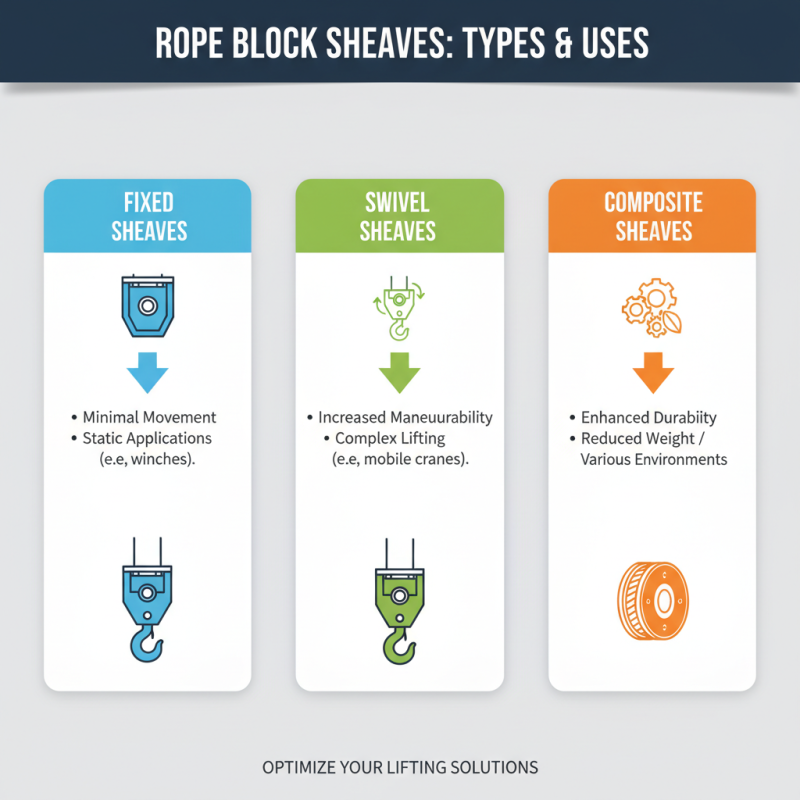

When it comes to optimizing lifting solutions, understanding the different types of rope block sheaves is crucial. Rope block sheaves can be categorized into several types, including fixed sheaves, swivel sheaves, and composite sheaves. Fixed sheaves are typically used in applications requiring minimal movement, while swivel sheaves offer increased maneuverability, making them ideal for complex lifting scenarios. Composite sheaves, on the other hand, combine materials to enhance durability and reduce weight, catering to a variety of lifting environments.

According to a report by the Lifting Equipment Engineers Association (LEEA), the efficient design of sheaves can increase lifting capacity by up to 25%, making the choice of sheave critical in heavy-duty applications. Additionally, the report highlights that using the appropriate sheave size and type can significantly decrease wear on ropes, extending their lifespan and improving overall safety in operations.

Tips: When selecting a rope block sheave, consider the load requirements and the environment in which it will be used. Additionally, ensure that the sheave aligns with the rope diameter to maximize efficiency. Regular maintenance checks on the sheave’s integrity can prevent unexpected equipment failures, ensuring a smoother and safer lifting process.

When selecting sheaves for efficient lifting solutions, several factors come into play that can significantly influence performance. The material of the sheave is paramount; common materials include steel, aluminum, and composite options. Steel offers high durability and strength, making it suitable for heavy loads, while aluminum is favored for its lightweight properties and resistance to corrosion. Composite materials provide a balance between weight and strength, making them versatile for various lifting scenarios.

Another critical aspect is the diameter of the sheave, which affects the operation of the lifting system. Larger sheaves reduce the bending stress on the rope, leading to enhanced lifespan and efficiency. Conversely, smaller sheaves are more compact and can fit into tighter spaces but may require careful consideration regarding rope wear and fatigue. Additionally, the groove design plays a vital role; wider grooves can accommodate various rope sizes and types, ensuring smoother operation and reducing the likelihood of rope slippage or damage during lifts.

By evaluating these factors—material, diameter, and groove design—users can select the most suitable sheaves to optimize lifting performance in their specific applications.

When it comes to optimizing lifting operations, the installation and maintenance of rope block sheaves play a critical role. Proper installation begins with selecting the right sheave size and material to ensure compatibility with the rope being used. It is essential to follow manufacturer guidelines when mounting the sheave, as correct alignment can significantly reduce friction and prevent premature wear. Additionally, securing the sheave firmly to its support structure ensures stability during operations, minimizing any risk of misalignment that could lead to failure.

Regular maintenance of rope block sheaves is vital for their longevity and efficiency. Periodic inspections should be conducted to check for signs of wear or damage, such as cracks on the sheave surface or excessive wear on the inner ridges. Lubrication is also crucial; using an appropriate lubricant can prevent rust and reduce friction. Cleaning the sheaves regularly removes debris that could impair function. Furthermore, replacing worn or damaged sheaves promptly can help maintain optimal lifting performance and safety. By adopting these installation and maintenance practices, operators can ensure their lifting solutions remain efficient and reliable over time.

Rope block sheaves play a crucial role in enhancing the efficiency and safety of lifting operations across various industries. According to a report by the International Organization for Standardization (ISO), improper use of sheaves can lead to premature wear and failure in lifting systems, resulting in increased operational costs and safety risks. To avoid these pitfalls, it is essential to adhere to best practices when using rope block sheaves.

One key best practice is to ensure that the sheaves are correctly matched to the rope type and diameter. As per data from the Lifting Equipment Engineers Association (LEEA), mismatched sheaves can cause significant wear on the rope, reducing its lifespan by up to 50%. Regular inspections should also be implemented to check for signs of wear and tear, such as surface degradation and deformation, which, if ignored, could lead to catastrophic failures during lifting operations. Additionally, lubricating the sheaves appropriately is vital to minimize friction and heat generation that can adversely affect both the sheave and the rope.

Furthermore, maintaining proper alignment during installation is vital for ensuring that the lifting operation runs smoothly. Misalignment can introduce unnecessary stress on both the sheave and the rope, increasing the likelihood of accidents. Implementing a training program for personnel involved in lifting operations can enhance their understanding of the best practices and promote a culture of safety and efficiency. A study conducted by the Occupational Safety and Health Administration (OSHA) highlights that organizations with comprehensive training programs see a reduction in workplace incidents by up to 30%, underscoring the importance of proper education in maximizing the potential of rope block sheaves.