In the rapidly evolving landscape of the oil and gas industry, the innovations in Oilfield Mud Pump technologies are pivotal in enhancing drilling efficiency and cost-effectiveness. According to a recent report by the International Energy Agency (IEA), the global demand for crude oil is projected to reach approximately 104 million barrels per day by the end of 2025, leading to heightened competition among oilfield operators to optimize their drilling operations. As a result, advancements in mud pump design and functionality have become crucial to support high-performance drilling processes and minimize operational downtime.

The adoption of smart technologies and automation within Oilfield Mud Pump systems has been identified as a key trend in the industry. Predictive maintenance and remote monitoring solutions are revolutionizing how operators manage their fleets, facilitating timely interventions that reduce the likelihood of equipment failure. A report published by MarketsandMarkets indicates that the global mud pump market is expected to witness significant growth, driven by increasing investments in offshore drilling and exploration activities. This surge in demand underscores the necessity for innovative solutions that enhance the reliability and efficiency of mud pumps.

Additionally, sustainability considerations are influencing the design and operation of Oilfield Mud Pumps. As regulatory frameworks become more stringent, companies are seeking to reduce their environmental footprint through the use of eco-friendly drilling fluids and energy-efficient pumping systems. The convergence of these trends highlights the critical role that Oilfield Mud Pump innovations will play in shaping the future of the drilling sector, ensuring that operators can meet both production goals and environmental responsibilities.

The oilfield mud pump technology is rapidly evolving, driven by the industry's continual pursuit of efficiency and sustainability. As we look toward 2025, several key innovations are set to reshape how drilling operations are conducted. Notably, advancements in variable frequency drive (VFD) systems are enhancing the control and performance of mud pumps, allowing operators to optimize energy consumption while minimizing wear and tear. According to recent industry reports, this technology can improve energy efficiency by up to 30%, significantly reducing operational costs.

Additionally, the integration of IoT (Internet of Things) technologies into mud pump operations is becoming increasingly prevalent. These smart pumps are equipped with sensors that monitor performance in real-time, providing crucial data analytics that can help in predictive maintenance. A report from the Society of Petroleum Engineers indicates that utilizing IoT in drilling operations can lead to a reduction in downtime by about 20%, allowing for a more streamlined and cost-effective drilling process.

Tips: Operators considering transitioning to newer mud pump technologies should closely evaluate their specific operational needs and potential ROI. Investing in training for personnel to effectively manage and leverage these advanced systems can also dramatically increase both safety and productivity. Furthermore, keeping abreast of the latest industry trends and innovations will ensure that companies remain competitive in a rapidly changing market.

In 2025, the oilfield mud pump industry is poised to undergo significant transformations driven by technological advancements and environmental considerations. One of the key trends shaping mud pump performance is the integration of smart technologies. These innovations enable real-time monitoring and data analysis, allowing operators to optimize pump efficiency and reduce downtime. Smart pumps can adapt their performance based on varying drilling conditions, ensuring that energy consumption is minimized while maximizing output.

Another vital trend is the shift towards sustainable practices. As the industry faces increasing pressure to reduce its carbon footprint, manufacturers are focusing on developing mud pumps that utilize environmentally friendly materials and energy-efficient designs. This transition not only meets regulatory requirements but also appeals to a growing consumer demand for sustainable solutions. Additionally, advancements in materials science are leading to the production of more durable and corrosion-resistant pumps, which can withstand harsher drilling environments, further enhancing operational lifespan and reliability. Overall, these trends signify a pivotal shift towards more intelligent and sustainable practices in the oilfield mud pump sector by 2025.

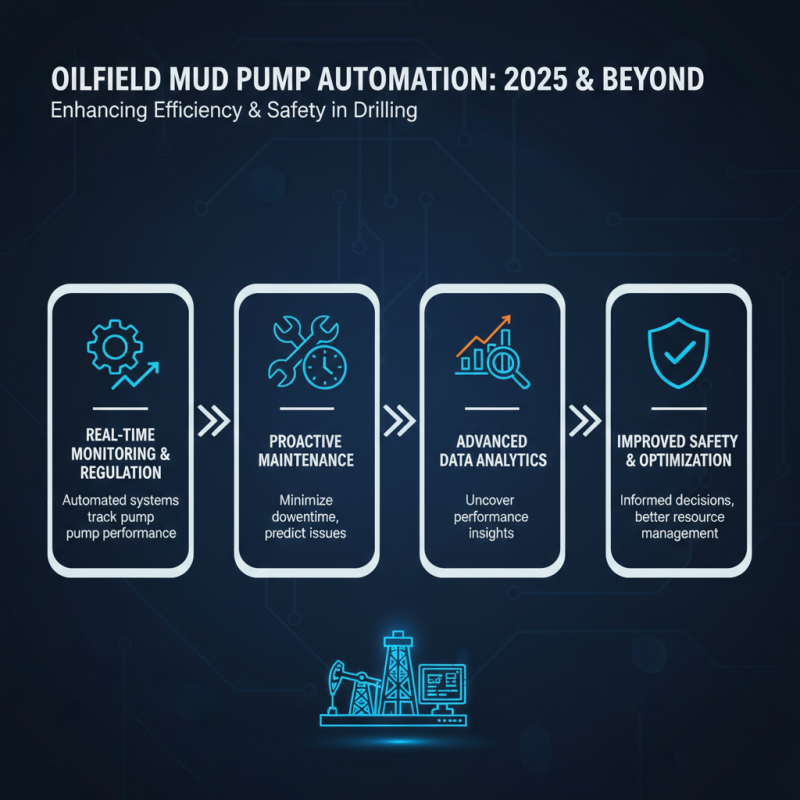

Automation is set to transform the oilfield mud pump sector significantly by 2025, enhancing both efficiency and safety in drilling operations. As the industry embraces smarter technologies, automated systems are being designed to monitor and regulate mud pump performance in real-time. This shift allows for proactive maintenance, minimizing downtime and optimizing resource management. Through advanced data analytics, operators can gain insights into pump performance that were previously unattainable, enabling them to make informed decisions quickly.

Furthermore, automation reduces the reliance on manual labor, which is particularly beneficial in remote and hazardous environments. By utilizing robotics and AI-driven systems, tasks that posed risks to human workers can be automated, thus improving overall safety on the drilling site. This trend not only leads to a more efficient workflow but also helps in addressing the industry's labor shortages. As companies invest in automation technologies, the expectation is that oilfield mud pumps will become more reliable and responsive, adapting to the dynamic conditions of drilling operations while ensuring optimal mud circulation and pressure control.

As the oil and gas industry increasingly faces scrutiny over its environmental impact, sustainability and regulatory frameworks are driving significant innovations in mud pump designs for oilfields. Emphasizing eco-friendliness, manufacturers are focusing on creating pumps that minimize energy consumption and waste generation throughout their lifecycle. This includes the development of more efficient hydraulic systems that not only improve operational performance but also reduce the carbon footprint associated with mud circulation processes.

New materials and technologies are being adopted to enhance the durability and efficiency of mud pumps while aligning with growing environmental regulations. For instance, closed-loop systems are being incorporated to recycle drilling fluids, significantly decreasing the volume of waste that typically requires disposal. Additionally, advancements in monitoring and control systems allow operators to track and optimize performance in real-time, further supporting sustainability efforts. These innovations not only comply with stringent regulations but also help operators remain competitive in a rapidly evolving industry landscape, where eco-conscious practices are becoming a necessity rather than an option.

| Innovation/Trend | Description | Impact on Sustainability | Regulatory Influence |

|---|---|---|---|

| Smart Mud Pumps | Incorporation of IoT technology for real-time monitoring. | Enhanced efficiency leading to reduced waste. | Compliance with advanced operational standards. |

| Eco-Friendly Mud Solutions | Biodegradable drilling fluids that minimize environmental impact. | Lower toxicity levels enhance ecosystem protection. | Regulations promote the use of non-toxic materials. |

| Hybrid Power Solutions | Integration of renewable energy sources. | Reduces reliance on fossil fuels, lowering carbon footprint. | Adherence to stricter emissions regulations. |

| Data Analytics | Advanced analytics to optimize pump performance. | Improved resource management and efficiency. | Supports compliance with reporting mandates. |

| Modular Pump Designs | Flexibility in assembly and maintenance of mud pumps. | Extended lifespan of components reduces waste. | Alignment with best practices in equipment standards. |

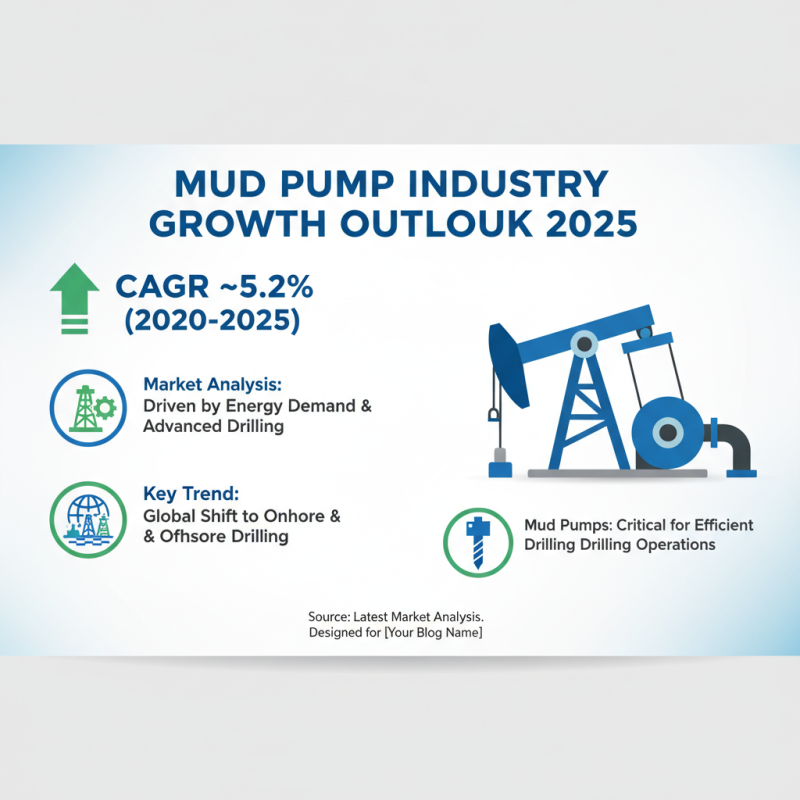

The mud pump industry is poised for significant growth, with projections estimating a compound annual growth rate (CAGR) of around 5.2% through 2025. According to the latest market analysis, the rising demand for energy resources and advancements in drilling technologies are key drivers behind this trend. The global shift towards onshore and offshore drilling projects highlights the critical role mud pumps play in maintaining efficient drilling operations, thus emphasizing their necessity in the oilfield sector.

As companies strive to enhance operational efficiency and reduce costs, innovation in mud pump technology is becoming increasingly prevalent. Recent reports suggest that developments such as automation, real-time monitoring systems, and improved materials for durability are at the forefront of industry trends. These innovations not only enhance performance but also minimize maintenance downtime, allowing for higher productivity levels in oil and gas extraction.

Tip: To stay competitive in the evolving market, companies should invest in training for their technicians on the latest mud pump technologies. This investment not only improves operational efficiency but also ensures that teams can respond swiftly to emerging challenges within drilling operations. By keeping abreast of technological advancements and industry trends, businesses can better position themselves for future growth.