In the dynamic fields of hoisting and rigging, the efficiency of operations heavily relies on the components utilized within the systems. Among these, Rope Block Sheaves are vital components that significantly enhance performance and safety during lifting tasks. According to industry reports by the Material Handling Industry (MHI), improper rigging procedures can lead to serious accidents, costing companies not only in potential fines but also in lost productivity. Investing in high-quality Rope Block Sheaves can mitigate these risks by enabling smoother and more effective handling of loads.

The demand for efficient lifting solutions continues to grow, fueled by advancements in material and design technology. The global hoisting and rigging equipment market is projected to expand at a compound annual growth rate (CAGR) of over 5% through 2025, highlighting the essential role that components like Rope Block Sheaves play in this evolution. These sheaves facilitate better load distribution, reduce wear and tear on ropes, and enhance overall system longevity, leading to more reliable and efficient operations. As companies strive to optimize their hoisting and rigging efforts, the choice of Rope Block Sheaves becomes an integral aspect of their operational strategy.

Rope block sheaves play a pivotal role in hoisting mechanisms, serving as the critical components that guide and support ropes during lifting operations. These sheaves are designed to reduce friction, improve efficiency, and enhance the overall functionality of rigging systems. When a rope travels over a well-engineered sheave, it minimizes wear and tear on both the rope and the sheave itself, enabling smoother movement and greater control. This efficiency is particularly important in heavy-duty applications where substantial loads need to be managed safely and effectively.

In addition to enhancing the mechanical performance of hoisting equipment, rope block sheaves contribute to the safety and reliability of rigging operations. Properly designed sheaves ensure that the rope is aligned correctly, preventing undue stress or misalignment that could lead to equipment failure. By maintaining optimal tension and direction in the hoisting system, these sheaves help to prevent accidents that could result from rope slippage or snapping. Furthermore, the use of high-quality materials and precise engineering in the manufacture of rope block sheaves ensures longevity and resilience, making them indispensable for efficient and safe hoisting and rigging practices across various industries.

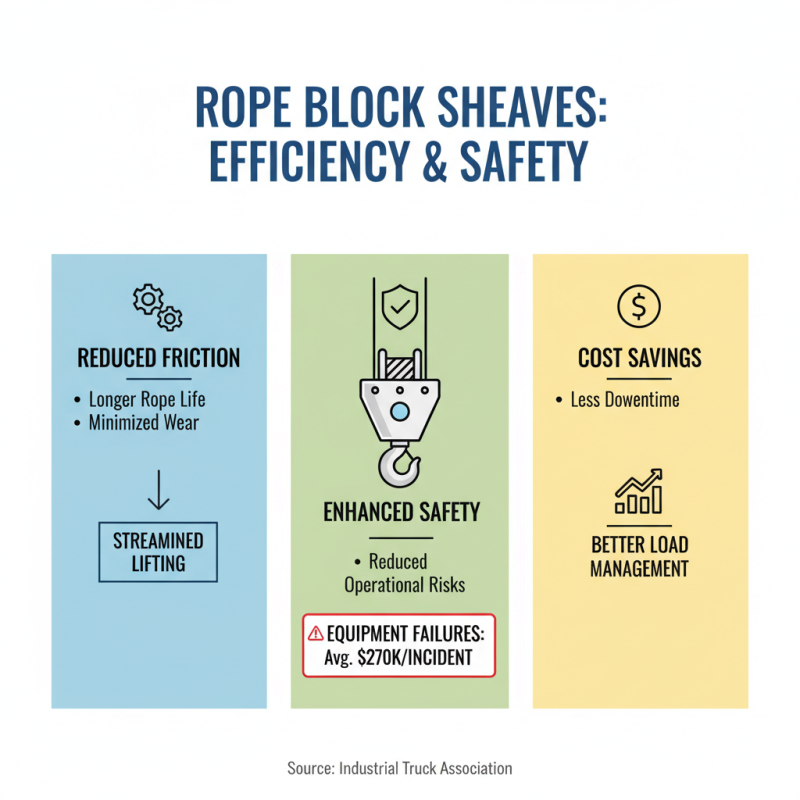

Rope block sheaves play a vital role in enhancing the efficiency and safety of hoisting and rigging operations across various industries. Utilizing high-quality sheaves can significantly reduce friction during lifting tasks, thus prolonging the life of the ropes and minimizing wear. According to a report by the Industrial Truck Association, equipment failures in rigging operations due to improper sheave usage can lead to downtime costing companies an average of $270,000 per incident. By employing sheaves specifically designed for rope applications, operators can benefit from streamlined lifting mechanics which translates to better load management and reduced operational risks.

One key advantage of rope block sheaves is their contribution to improved load distribution. Research from the International Association of Drilling Contractors suggests that utilizing the correct sheave size and material directly impacts the effectiveness of load handling, with properly configured systems capable of handling loads up to 50% more efficiently. This not only leads to safe rigging practices but also enhances productivity, allowing crews to complete tasks faster while ensuring that safety standards are met. When organizations invest in premium rope block sheaves, they are not just enhancing mechanical performance, but also paving the way for a safer and more efficient working environment.

Rope block sheaves are critical components in hoisting and rigging operations, providing essential support for the smooth and efficient movement of loads. There are various types of rope block sheaves, each designed for specific applications that enhance operational efficiency. For instance, standard sheaves are often utilized in construction and industrial applications, where robust load management is necessary. Their design facilitates the efficient transfer of force through ropes, minimizing friction and wear, which leads to improved longevity and performance.

In contrast, specialized sheaves, such as those designed with grooves tailored for synthetic ropes, are prevalent in marine and nautical settings. According to the Rigging and Lifting Report 2022, the use of high-performance sheaves can increase lifting efficiency by up to 25%, significantly reducing energy expenditure and enhancing safety during operations. Additionally, composite sheaves are gaining popularity in various sectors due to their lightweight properties and resistance to corrosion, making them suitable for both onshore and offshore applications. The choice and application of the right type of rope block sheave are vital for meeting the demands of modern lifting tasks while ensuring reliability and safety in dynamic work environments.

Rope block sheaves play a critical role in the efficiency of hoisting and rigging operations, and their maintenance is paramount for ensuring safety and performance. Industry reports indicate that over 30% of rigging-related accidents are caused by improper equipment maintenance, highlighting the importance of routine inspections and upkeep of rope block sheaves. Regularly checking for wear and tear, including surface damage and misalignment, can help prevent failures that could result in costly downtime and potentially severe injuries.

Maintenance best practices for rope block sheaves include regular lubrication to minimize friction, as the reduction in wear can extend the lifespan of the sheaves significantly. According to a 2022 study by the International Organization for Standardization (ISO), proper lubrication can enhance the efficiency of the sheave by up to 15%, making it easier for operators to lift heavy loads without straining the equipment. Additionally, it is crucial to inspect the sheave's alignment with the rope path to avoid undue stress, which can compromise both sheave and rope integrity. Implementing a consistent maintenance schedule based on operating conditions and frequency of use will ensure that these critical components remain in optimal condition, thus supporting safe and efficient operations.

When utilizing rope block sheaves in hoisting and rigging operations, safety should always be a priority. According to industry statistics, approximately 40% of workplace injuries involve lifting and hoisting activities. To mitigate these risks, it is crucial to ensure that all equipment, including sheaves, is in optimal condition. Regular inspections can reveal wear and tear that could compromise safety; for instance, sheave grooves should be checked for deformation, as even minor imperfections can lead to catastrophic failures.

In addition, operators must be trained to understand load limits and proper rigging techniques. The American Society of Civil Engineers (ASCE) recommends that operators do not exceed specified weight capacities marked on equipment. Overloading sheaves can result in sudden failures, leading to severe injuries or fatalities. Implementing clear lifting plans and safety protocols can significantly reduce the incidence of accidents.

Tips: Always have a designated safety officer on-site during rigging operations to oversee procedures and ensure compliance with safety standards. It's also beneficial to conduct regular safety drills, so all team members are familiar with emergency protocols should an incident occur. Moreover, using proper PPE (Personal Protective Equipment) tailored for lifting activities can further ensure the well-being of all personnel involved.

| Characteristic | Importance | Safety Consideration |

|---|---|---|

| Material Type | Durability and strength under load | Ensure materials meet safety standards |

| Sheave Size | Optimal for specific rope sizes and loads | Correct sizing prevents rope wear |

| Bearing Type | Smooth operation and reduced friction | Regular maintenance prevents failure |

| Load Rating | Ensures the sheave can handle expected loads | Do not exceed load ratings during use |

| Lubrication | Reduces wear and prolongs service life | Use appropriate lubricants for safety |