Rope Block Sheaves play a crucial role in the world of heavy lifting. These components are often overlooked, yet they are essential for ensuring efficiency and safety. They are designed to guide and support ropes, allowing for smooth movement during lifting operations. Without them, lifting heavy loads would become unpredictable and dangerous.

In various industries, Rope Block Sheaves must withstand immense weight and stress. The right sheave can reduce friction, allowing better load distribution. This optimization dramatically enhances the lifting process. However, not all sheaves are made equal; quality and design matter significantly. Choosing the wrong type can lead to accidents and equipment failure.

When considering Rope Block Sheaves, one must reflect on their importance. Are we prioritizing quality over cost? Optimal performance requires investment and thorough understanding. While they may seem like simple components, their impact on heavy lifting is undeniable. The right sheave can prevent complications down the line, illustrating the need for careful thought in selection.

Rope block sheaves play a pivotal role in heavy lifting operations. They help distribute weight evenly and reduce friction. This allows for smoother movement of loads, which is essential when lifting heavy items. Without them, the risk of accidents increases significantly. Operators must understand how sheaves function to maximize their effectiveness.

In heavy lifting, precision is key. Sheaves must be of the correct size and material to handle specific loads. A mismatch can lead to wear and tear, even failure of the lifting system. The alignment of sheaves affects how pulleys perform, impacting safety and efficiency.

In practice, proper maintenance is often overlooked, which can lead to costly mistakes. Regular checks are necessary yet sometimes neglected.

Operators need to be aware of their limitations. Relying solely on technology can be risky. Human judgment is still crucial in assessing the conditions and loads. Training can deepen understanding but doesn't eliminate all potential errors. Awareness of these variables can lead to better decision-making and safer lifting practices.

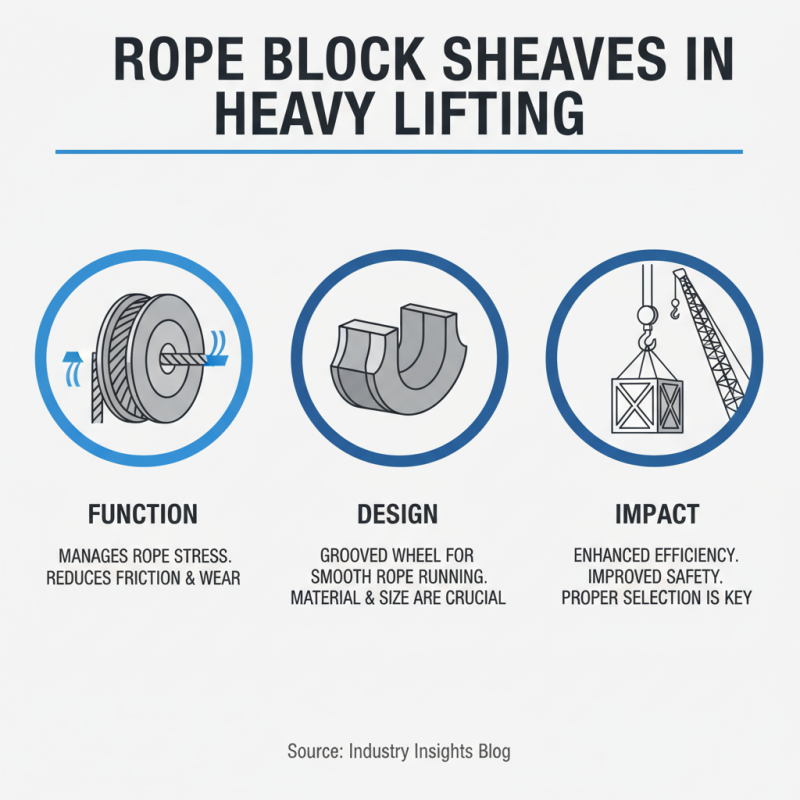

Rope block sheaves play a critical role in heavy lifting operations. These pulleys effectively manage the stress exerted on ropes during lifting tasks. The designed grooves allow ropes to run smoothly, reducing friction and wear. A sheave’s material and size impact overall performance significantly. Proper selection can lead to enhanced efficiency and safety in heavy lifts.

When planning a lifting operation, understanding the mechanics of rope block sheaves is crucial. They transfer the load, making it easier to lift heavy weights. However, even minor variations in alignment can cause complications. Users must ensure that the sheaves are correctly positioned and maintained. Neglecting this aspect can lead to unexpected failures.

Maintaining a keen eye on factors like rope tension and wear is essential. A worn sheave can add risk to the lifting process. Regular inspections help identify and rectify issues before they escalate. That said, mistakes happen. It's important to learn from missteps and adapt practices accordingly. Emphasizing the mechanical properties of sheaves can enhance both safety and functionality in heavy lifting situations.

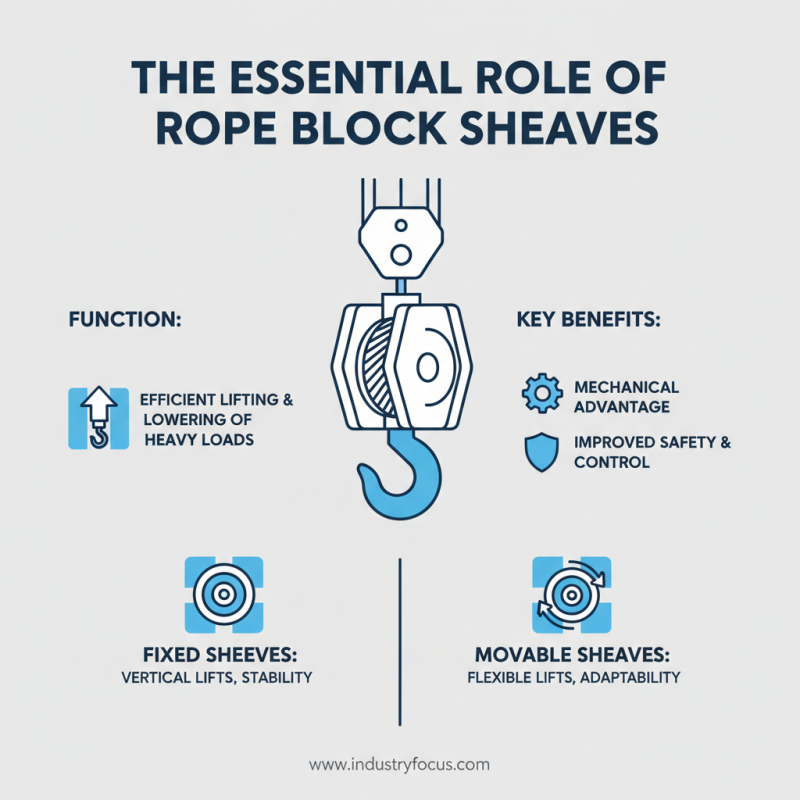

Rope block sheaves play a vital role in various industries. They are crucial for efficient lifting and lowering of heavy loads. Different types of sheaves are used depending on specific lifting needs. For example, fixed sheaves provide stability for vertical lifts, while movable sheaves allow for more flexibility in lifting scenarios.

According to industry studies, the construction sector accounted for nearly 40% of the demand for sheaves in 2022. Heavy equipment often relies on these components for safe operations. However, a report by the Machinery Safety Council emphasizes the importance of regular maintenance. Neglect can lead to wear and eventual failure, compromising safety.

In marine applications, sheaves must withstand corrosive environments. Stainless steel materials are often preferred. Yet, the durability of sheaves can be affected by environmental conditions. The oil and gas industry demands resilient sheaves capable of handling immense weight. Yet, data shows that improper installation can reduce their lifespan significantly. Addressing these factors is critical for maintaining operational efficiency.

Rope block sheaves play a critical role in heavy lifting operations. However, safety is a primary concern when using them. Over 30% of workplace injuries in construction involve lifting equipment. Properly assessing the sheave's condition can significantly reduce these risks.

One key safety consideration is the load limit. Most sheaves are rated for specific weights. Exceeding this limit can lead to catastrophic failure. For instance, a well-maintained sheave rated for 10 tons can break if overloaded. Regular inspections are essential, especially for signs of wear or damage. Lack of oversight often leads to accidents.

Another aspect is the environment where the sheaves are used. High temperatures can affect the material integrity. The National Institute for Occupational Safety and Health (NIOSH) indicates that nearly 25% of accidents occur under extreme conditions. Workers must be trained to assess potential hazards thoroughly. Communication within the team is crucial. Misunderstandings about load distribution often lead to significant problems, emphasizing the need for a clear protocol.

This chart demonstrates the load capacity of rope block sheaves in relation to different weights of loads. A clear decline in load capacity percentage is observed as the weight increases, highlighting the importance of selecting the appropriate sheave for safety in heavy lifting operations.

When it comes to heavy lifting, rope block sheaves play a critical role in ensuring efficiency and safety. Their design helps to minimize friction and distribute weight effectively. However, without proper maintenance, even the best sheaves can falter. Regular inspections are key. Look for signs of wear or damage. A small crack can lead to failure during a load lift.

Often, operators overlook the importance of lubrication. Keeping sheaves well-lubricated reduces wear and tear. Use the right type of lubricant, as specified in your maintenance guidelines. Avoid excessive grease, which can attract debris and create more problems. A clean sheave runs smoother and extends its lifespan.

In addition to lubrication, ensure proper alignment. Misalignment can cause premature wear. Check the positioning regularly, especially after heavy use. Sometimes, a simple adjustment can make all the difference. Ask yourself if you are performing these checks consistently. Remember, neglecting maintenance is a step towards safety risks in heavy lifting operations.