In industrial systems, safety is paramount. A critical component for ensuring safety is the Safety Relief Valve. This device acts as a safeguard, preventing excessive pressure buildup within systems. When pressure exceeds safe levels, the valve opens, allowing excess gas or liquid to escape. This action protects equipment from damage and reduces the risk of catastrophic failures. Many industries depend on these valves, from oil and gas to pharmaceuticals.

Neglecting the importance of a Safety Relief Valve can lead to serious consequences. Failures may cause explosions or hazardous leaks. It is vital to regularly inspect and maintain these valves. Over time, wear and tear can diminish their effectiveness. Reflecting on past incidents reveals that a simple oversight in valve maintenance resulted in significant losses. Ensuring optimal operation of the Safety Relief Valve is crucial for safe industrial processes.

In conclusion, the Safety Relief Valve is not just a component; it is a lifeline for industrial systems. Understanding its role helps prevent accidents. A proactive approach to maintenance and awareness can significantly enhance overall safety. Every aspect counts in maintaining industrial integrity.

A safety relief valve is a key component in industrial systems. It helps prevent excessive pressure buildup, which can lead to catastrophic failures. These valves automatically release pressure when it exceeds preset limits. This mechanism protects equipment and personnel in plants and factories.

One important tip for maintaining these valves is regular inspection. Check for signs of wear or corrosion. Ensure they open and close properly. Neglecting this can result in serious risks.

Another consideration is the sizing of safety relief valves. A valve that is too small can’t handle pressure spikes. Conversely, an oversized valve may lead to excessive venting. Accurate sizing is crucial to ensure safety and efficiency in operations.

Remember, safety relief valves are not just accessories; they are essential. Investing time and resources in their maintenance and sizing can save lives and prevent costly damages.

| Dimension | Details |

|---|---|

| Definition | A safety relief valve is a mechanical device designed to automatically release pressure from a system when it exceeds a predetermined limit. |

| Function | To protect equipment and systems from excessive pressure by allowing controlled release of fluids or gases. |

| Industries using Safety Relief Valves | Chemical manufacturing, oil and gas, power generation, pharmaceuticals, and food processing. |

| Common Applications | Pressure vessels, boilers, pipelines, and reactors. |

| Importance | They prevent catastrophic failures, protect human life, and ensure compliance with safety regulations. |

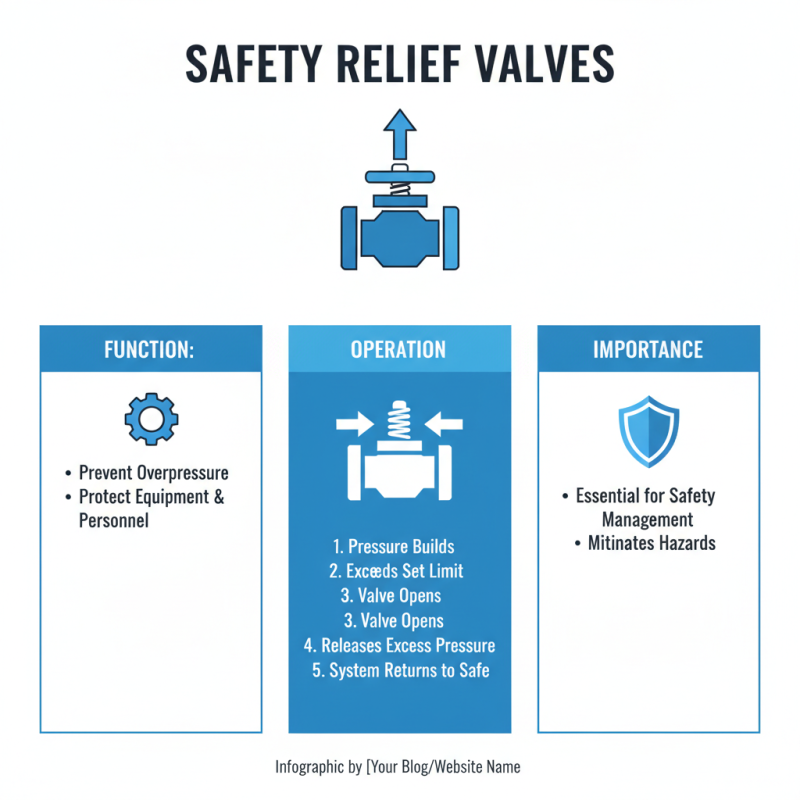

Safety relief valves play a crucial role in industrial systems. They prevent overpressure, protecting equipment and personnel from potential hazards. When pressure builds beyond a set limit, the valve opens. This action releases excess pressure. It allows the system to return to a safe operating condition. Understanding how these valves operate is essential for effective safety management.

The mechanism of a safety relief valve is relatively straightforward. Most valves work on a spring-loaded mechanism. The spring holds the valve closed against the pressure. Once the pressure exceeds the preset value, the spring compresses. The valve then opens, allowing fluids or gases to escape. This quick action is vital for preventing catastrophic failures.

Tip: Regular maintenance is key. Inspect the valves periodically to ensure they function correctly. Problems can arise if debris blocks the valve. Ensure the area around the valve is clean and accessible.

It’s important to note that not all valves are created equal. Sometimes, a valve may not seat properly after opening. This can lead to leaks, which pose safety risks. Keep an eye on valve performance. Reflections on its functionality can lead to better safety protocols.

Safety relief valves are crucial in industrial systems. They prevent overpressure situations, which can cause catastrophic equipment failures. When pressure builds too high, these valves release excess pressure. This process protects not only the equipment but also the workers nearby.

In many industries, a sudden pressure spike can lead to explosions or leaks. Imagine a vessel filled with gas. If it doesn't have a functioning safety relief valve, the consequences could be dire. It's not just about equipment—it’s about lives. Regular maintenance and testing of these valves is essential, yet often overlooked.

Sometimes, operators may neglect the importance of these components. They might assume that everything is functioning well. But without proper checks, a small issue can escalate. If valves fail to open when needed, the results can be disastrous. A proactive approach can save both assets and lives. Understanding the role of safety relief valves adds a layer of security in industrial environments.

Safety relief valves are crucial for preventing overpressure situations in industrial systems. These valves must comply with various standards and regulations that ensure their reliability. In the United States, the American Society of Mechanical Engineers (ASME) provides guidelines for the design and testing of these safety devices. Compliance is not optional; it ensures the safety of personnel and equipment. According to a report by the National Board of Boiler and Pressure Vessel Inspectors, improper functioning of safety relief valves accounts for 27% of industrial accidents.

In Europe, the Pressure Equipment Directive (PED) emphasizes safety and requires rigorous assessment of relief valves. This includes thorough examinations and regular maintenance checks. However, many companies face challenges in meeting these standards effectively. Some reports indicate that nearly 40% of facilities do not perform adequate testing of their safety relief valves, leading to potential hazards. Life-threatening incidents result when systems operate under unregulated pressure, causing catastrophic failures.

Furthermore, the global standard ISO 4126 outlines additional requirements, but adherence is inconsistent. Poor training and lack of knowledge often hinder compliance efforts. Many operators do not fully understand the importance of regular inspection. The gap in knowledge directly affects functional reliability, putting systems and lives at risk. Awareness and education are essential in navigating these complex regulations effectively.

Safety relief valves are crucial for preventing overpressure in industrial systems. Regular maintenance ensures they function properly. A study from the American Society of Mechanical Engineers reveals that 40% of valve failures occur due to inadequate maintenance practices. This is alarming.

Routine checks are needed. Inspecting for corrosion, leaks, and proper seating should happen often. A visual inspection can catch issues early. For instance, a valve that appears rusty might not function correctly under high pressure. It’s not just about replacement; it’s about the whole picture.

Data shows that 75% of industrial accidents could be avoided with proper maintenance protocols in place. Employees often overlook small signs of wear. This complacency can lead to dire consequences. Encouraging a culture of safety is essential. Training employees to recognize warning signs can make a difference.