Choosing the right drilling mud pumps is critical in the oil and gas industry. According to the Global Drilling Fluids Market report, the demand for effective drilling mud systems is projected to grow significantly. Drilling mud pumps are essential for maintaining circulation and transporting drilling fluid during operations.

Expert John Smith, a leading authority in drilling technologies, states, "Selecting the right pump can greatly influence operational efficiency and project costs." His insights underscore the importance of careful selection in drilling operations. Accurate pump selection minimizes downtime and optimizes resource flow.

When considering drilling mud pumps, factors like capacity, durability, and energy efficiency matter. Many companies overlook these aspects, leading to costly mistakes. As operations become more complex, a mindful approach to pump selection is necessary to ensure project success. An informed choice can mean the difference between a profitable venture and an operational setback.

When selecting a drilling mud pump, understanding the types available is crucial. There are primarily three kinds: centrifugal, positive displacement, and screw pumps. Each has its unique features and ideal applications. Centrifugal pumps are known for their efficiency at higher rates. They work well for lower viscosity fluids and are often used in large-scale operations.

Positive displacement pumps, on the other hand, excel in high viscosity fluids. They provide a consistent flow, which is essential in many drilling applications. Their design allows for excellent performance under pressure, making them reliable in challenging environments. Screw pumps are less common but offer unique advantages. They can handle a wide range of fluid types and are known for their smooth operation.

Choosing the right type depends on multiple factors, including the fluid's properties and the specific drilling conditions. Each pump type has trade-offs. Some may not perform well in all situations. It's essential to analyze operational needs carefully. Convenience and efficiency shouldn't overshadow the need for reliability. Reflecting on these aspects can lead to a more informed decision.

| Type of Pump | Fluid Type | Flow Rate (GPM) | Maximum Pressure (PSI) | Typical Application |

|---|---|---|---|---|

| Centrifugal Pump | Water-based Mud | 200-1000 | 50-150 | Shallow Drilling |

| Positive Displacement Pump | Oil-based Mud | 100-800 | 100-300 | Deep Well Drilling |

| Diaphragm Pump | Water-based Mud | 50-600 | 20-80 | Environmental Cleanup |

| Submersible Pump | Water-based Mud | 100-500 | 30-60 | Reservoir Drilling |

| Electric Pump | Water-based Mud | 200-2000 | 70-200 | High Volume Operations |

Choosing the right drilling mud pumps involves several key factors. First, consider the pump's flow rate. This is crucial for maintaining the drilling process efficiently. A pump that cannot keep up may lead to halted operations, causing delays and increased costs.

Next, look at the pump's pressure rating. This determines its ability to transport mud effectively through the drilling system. If the pressure is too low, muddy fluid may not reach the surface as needed. It's essential to match the pump’s capabilities with the requirements of your specific drilling project.

Material compatibility is another aspect to reflect on. Different mud compositions require specific materials to avoid corrosion or wear. A mismatch can lead to frequent repairs and losses. Assess the environment in which the pump will operate. Factors such as temperature and chemical exposure can significantly impact its performance. Each decision matters, and sometimes, the most evident choice is not the best one. Each project has unique challenges, so flexibility is vital.

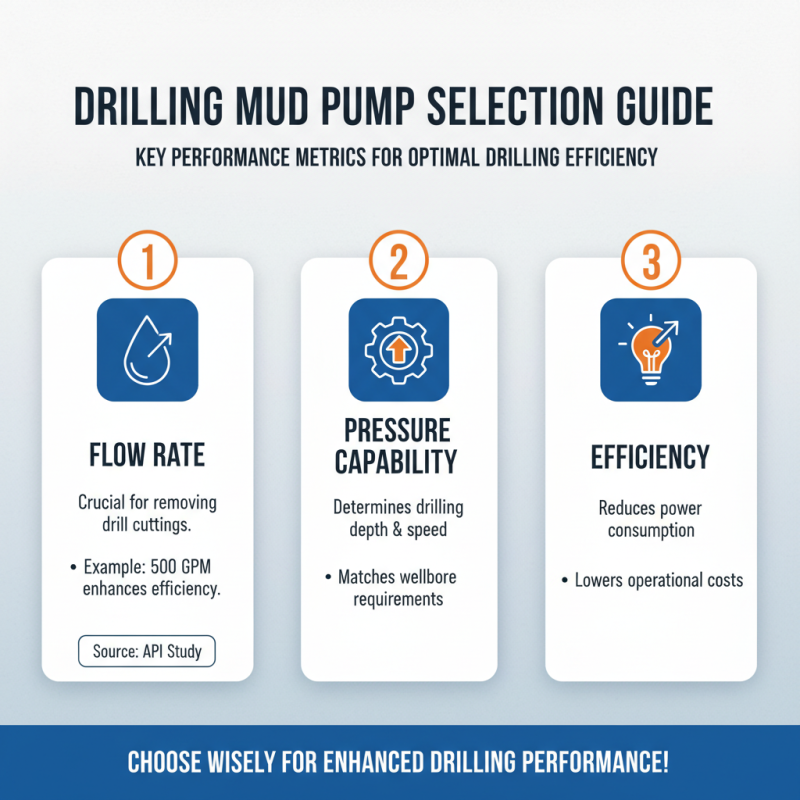

Choosing the right drilling mud pump is crucial. Pump performance metrics guide this choice. Key metrics include flow rate, pressure capability, and efficiency. According to a study by the American Petroleum Institute, optimal flow rates can significantly increase drilling efficiency. For example, pumps with a flow rate of 500 gallons per minute (GPM) can enhance the removal of drill cuttings effectively.

Pressure capability is another essential factor. The same study indicates that pumps must withstand pressures up to 5,000 psi in deepwater drilling. This capacity ensures that the mud circulates continuously, preventing issues like well blowouts. Efficiency ratings also matter; pumps with over 80% efficiency tend to minimize operational costs. However, some pumps fail to meet claimed specifications. Industry data shows that roughly 20% of pumps underperform, leading to delays and increased expenses.

Common mistakes occur when operators overlook these metrics. Choosing a pump that meets immediate needs can backfire later. Insufficient flow rates may slow down drilling or increase time spent on-site. Therefore, assessing each metric carefully ensures that the selected mud pump serves both short-term and long-term goals effectively. Metrics should be regularly reviewed to align with operational changes.

When it comes to drilling mud pumps, maintenance is key. Regular checks can significantly increase a pump's lifespan. It's essential to monitor fluid levels, as running on low can cause damage. Inspecting filters should be routine. A clogged filter can lead to poor performance or pump failure.

Pay attention to wear and tear. Components like valves and seals may degrade over time. Don’t push the pump to its limits. Overworking it can cause overheating and mechanical issues. Maintaining optimal operating conditions is crucial. A small change can make a big difference.

Documenting maintenance activities is important. It allows you to track patterns and identify issues early. However, keeping comprehensive records can be challenging. Instead of just noting the dates, detail the actions taken. This will provide better insight for future maintenance needs. Reflecting on past maintenance can help guide better practices. Choose wisely, and remember that every detail counts.

Understanding the maintenance requirements for drilling mud pumps is crucial for their longevity and efficiency. The following bar chart represents different types of mud pumps and their average maintenance frequency, which can help operators choose the best option for their needs.

When budgeting for drilling mud pumps, it's vital to analyze all costs involved. According to a recent industry report by the International Association of Drilling Contractors, the price of pumps can vary significantly based on their specifications. Basic models range from $15,000 to $30,000, while high-performance pumps can exceed $100,000. Understanding the full scope of expenses is key to avoiding overspending.

Operating costs also play a crucial role in the budget. Maintenance, energy consumption, and downtime can add up quickly. Reports indicate that maintenance costs can account for up to 20% of total operational expenses. When selecting a pump, consider its efficiency and reliability. A more efficient model might have a higher upfront cost but lower lifetime expenses.

It's essential to factor in potential unforeseen costs. Poor performance in extreme conditions can lead to higher repair bills. A bad choice can severely impact overall operations. Do thorough research before finalizing any decision. When it comes to drilling mud pumps, it's clear that upfront costs are only part of the equation. Budgeting should consider long-term operational efficiency and potential risks.