In the dynamic world of drilling operations, efficient and reliable equipment is paramount, and drilling mud pumps serve as a crucial component in this process. According to Dr. Emily Johnson, a leading expert in drilling technology, “The right drilling mud pump not only enhances performance but also minimizes operational costs, making it an essential tool for any successful drilling project.”

As we delve into the top 10 drilling mud pumps available in 2023, it becomes evident that understanding their features and benefits is key for professionals in the industry. These pumps are engineered to handle the demanding tasks of circulating drilling fluid, effectively managing the separation of cuttings and maintaining optimal pressure during drilling. In this guide, we will explore the various types of drilling mud pumps, their unique characteristics, and practical buying considerations that can help you make informed decisions for your drilling operations.

By equipping yourself with this knowledge, you’ll be better positioned to select a drilling mud pump that meets your specific needs, ensuring enhanced efficiency and productivity in your endeavors.

Drilling mud pumps play a crucial role in the drilling industry, primarily facilitating the circulation of drilling fluids, also known as mud, through the drilling system. These pumps are essential for maintaining the well’s stability, preventing blowouts, and ensuring the efficient removal of cuttings during the drilling process. The use of drilling mud not only cools and lubricates the drill bit but also helps to maintain pressure in the wellbore, making the selection of the right mud pump paramount for successful drilling operations.

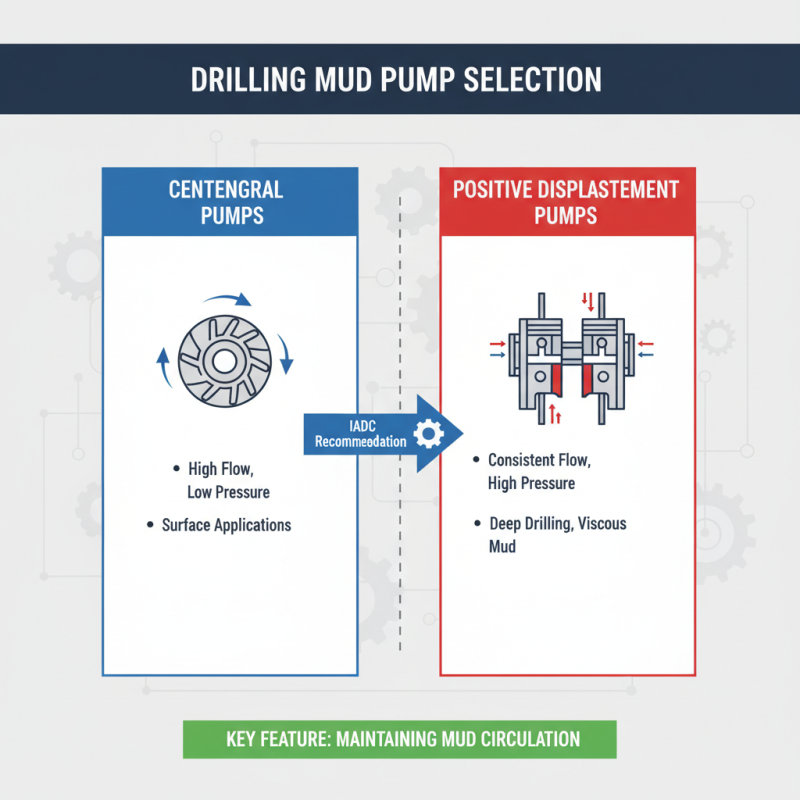

When considering the purchase of a drilling mud pump, it's important to assess the specific needs of your drilling project. Factors such as flow rate, pressure requirements, and the type of drilling fluid are critical in determining the most suitable pump. Remember that there are various types of mud pumps, including centrifugal and positive displacement pumps, each with its advantages depending on the application.

Tips: Always evaluate the total cost of ownership, including maintenance and operational expenses, rather than just the initial purchase price. Additionally, understand the pump's compatibility with various drilling fluids, as this can significantly affect performance and longevity in the field. Make sure to consult with industry experts or specifications to align your choice with your project’s demands. Choosing the right pump can enhance efficiency and reduce downtime, contributing to overall project success.

When selecting a drilling mud pump, several key features play a crucial role in ensuring efficiency and reliability in drilling operations. One of the primary considerations is the pump type, which can range from centrifugal to positive displacement pumps. According to the International Association of Drilling Contractors (IADC), positive displacement pumps are often preferred in high-viscosity drilling environments due to their ability to maintain a steady flow rate under varying pressure conditions. This characteristic is particularly critical in deep drilling applications, where maintaining mud circulation can significantly influence the success of the drilling process.

Another essential feature to consider is the pump's capacity and pressure rating. Data from the Society of Petroleum Engineers (SPE) indicates that selecting a pump with an appropriate flow rate—typically between 500 to 3000 liters per minute—can dramatically affect the efficiency of the drilling operation. Higher pressure ratings enable the pump to handle dense drilling muds, ensuring that cuttings are effectively transported to the surface. Additionally, the material construction of the pump, often dictated by compatibility with drilling fluids, should be assessed to prevent wear and increase the pump's lifespan under strenuous conditions.

Lastly, the ease of maintenance should not be overlooked. A report from the American Petroleum Institute (API) emphasizes that pumps designed for quick disassembly and reassembly significantly reduce downtime during maintenance. Features such as modular design and easy access to critical components can facilitate streamlined service and increase overall pumping efficiency. By prioritizing these features, operators can optimize their drilling fluids management and enhance the overall performance of their drilling operations.

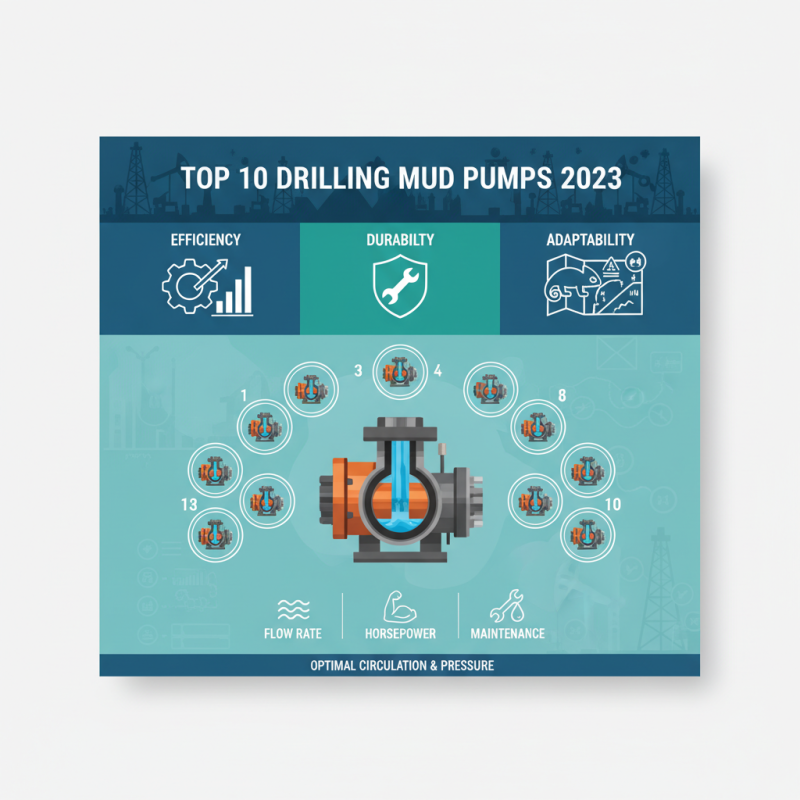

When selecting a drilling mud pump, understanding the characteristics and performance of each model is paramount. The top 10 drilling mud pumps of 2023 have been evaluated based on their efficiency, durability, and adaptability to varying drilling conditions. These pumps are designed to handle the high viscosity and density of drilling mud, ensuring optimal circulation and pressure maintenance throughout the drilling process. Evaluating factors such as flow rate, horsepower, and maintenance requirements can help operators make informed decisions tailored to their specific needs.

In the reviews and comparisons of these leading models, features such as ease of installation, noise levels, and energy consumption are also discussed. Additionally, aspects like portability and compatibility with existing drilling systems are significant considerations for users aiming to enhance their drilling operations. By highlighting the benefits of each pump, potential buyers can better understand how to improve their drilling efficiency and reduce downtime, ultimately leading to a more productive drilling project.

The use of high-quality drilling mud pumps in operations offers several key benefits that enhance efficiency and performance in drilling projects. First and foremost, these pumps are designed to provide reliable and consistent flow rates, which are critical in maintaining the pressure required to circulate drilling fluids. This consistency not only improves the overall safety of the drilling operation by preventing blowouts but also ensures that the drilling process remains smooth and uninterrupted. When the mud pump functions optimally, it helps in keeping the drilling fluids at the right density and viscosity, allowing for better cuttings removal and wellbore stability.

Additionally, high-quality drilling mud pumps often come equipped with advanced features that contribute to their durability and ease of maintenance. Features such as self-priming capabilities and modular designs make these pumps easier to service and reduce downtime. The robustness of these units is instrumental in minimizing wear and tear, thus extending their lifespan and lowering operational costs. Furthermore, by investing in superior mud pumps, operators can enhance the overall productivity of their drilling operations, as these pumps are built to handle a wide range of drilling conditions, even in the most challenging environments. As a result, enhancing the quality of drilling mud pumps can lead to significant long-term benefits for companies in the oil and gas industry.

When considering the purchase of a drilling mud pump, it is crucial to evaluate several key factors that can significantly influence your decision. First, the pump's efficiency and capacity are paramount; these factors directly impact the overall performance of drilling operations. According to a 2022 market study by Research and Markets, the demand for high-capacity mud pumps has increased by 30% as companies strive for better drilling efficiency. Choosing a pump with the appropriate flow rate, typically ranging from 100 to 2500 gallons per minute, ensures optimal mud circulation and enhances the effectiveness of drilling fluids.

Another critical factor is the pump's material construction and durability. In demanding drilling environments, pumps must withstand heavy wear and harsh conditions. The Global Oil and Gas Industry Report highlights that pumps made from corrosion-resistant materials can last up to 50% longer than standard options, leading to reduced maintenance costs and downtime. Additionally, considering the ease of maintenance and accessibility of spare parts is vital for maintaining operational efficiency in the long run. Many companies are now prioritizing these attributes, ensuring that their investments yield reliable performance and longevity in various drilling operations.