In the world of pressure management, the role of the Safety Relief Valve is critical. Dr. John Smith, a renowned expert in pressure safety systems, once stated, "The right Safety Relief Valve can prevent catastrophic failures." This highlights the importance of selecting the appropriate valve type for different applications.

Safety Relief Valves come in various types, each designed for specific operational needs. Understanding these differences is vital for industry professionals. For example, the spring-loaded valve is common, yet its efficiency depends on correct installation. Many overlook this aspect, which can lead to unforeseen failures.

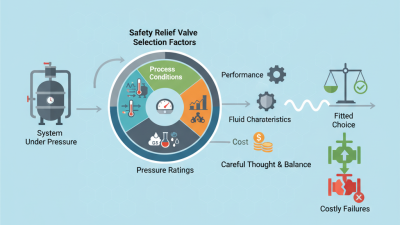

Choosing the right Safety Relief Valve involves more than just product specs. It requires analyzing system requirements and potential failure modes. Too often, companies use a one-size-fits-all approach, which can be detrimental. Adapting to individual needs can enhance safety and reliability.

Safety relief valves are essential in managing pressure within industrial systems. They help prevent dangerous overpressure situations. The importance of these valves cannot be overstated. They are often the last line of defense against catastrophic failures. When pressure builds beyond safe limits, these valves open to release excess pressure.

Many types of safety relief valves exist. Each serves a specific purpose. Compression, thermal, and vacuum applications all use different designs. Some may have issues like sticking or improper sizing. These problems can compromise safety. Regular maintenance is crucial. Inspecting valves helps ensure they function correctly and meet safety standards.

Understanding the different types of safety relief valves improves safety management. Knowledge of their operation leads to better decisions in pressure control strategies. Organizations should prioritize training and awareness. An informed team can react effectively when pressure anomalies occur. Proper use of safety relief valves is key to a safe working environment.

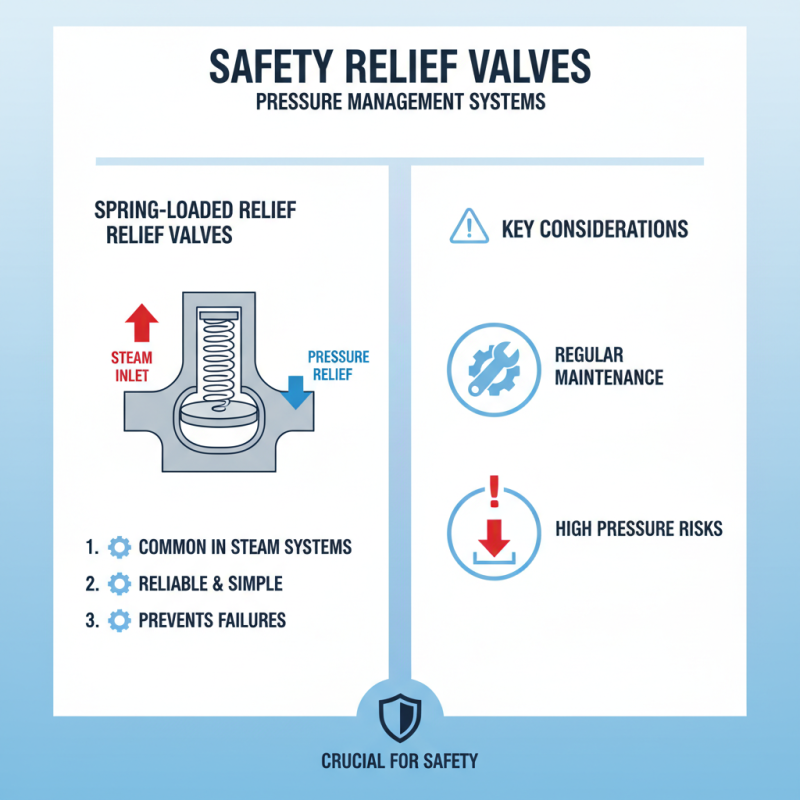

Safety relief valves play a crucial role in pressure management systems across various industries. Each type serves unique applications. For instance, spring-loaded relief valves are commonly used in steam systems. They are reliable and simple. In areas dealing with high steam pressure, these valves can prevent catastrophic failures. However, they require regular maintenance to ensure effective operation.

Another type is the pilot-operated relief valve. These valves are preferred in large systems due to their accuracy. They maintain optimal pressure levels effectively. However, their complexity can lead to challenges during repairs. The need for a skilled technician is essential in these cases.

Tips: Regularly inspect all relief valves for wear and tear. A small issue can escalate quickly. Know the specific application for each valve type. The wrong valve can lead to operational failures.

In chemical plants, there are burst discs. They act as failsafe devices. However, they lack the ability to reopen. This can create challenges in emergencies. Understanding the pros and cons of each type improves safety protocols. Too often, facilities overlook these critical components, potentially risking safety. Proper training for staff is vital. Recognizing the importance of these valves ensures better pressure management.

When selecting a safety relief valve, there are several key features to consider. The valve’s set pressure is critical. It determines when the valve opens. You want it to trigger at the right pressure for your system. An incorrect setting can lead to catastrophic failures. Take time to understand the specific pressure requirements of your application.

Another important feature is the valve sizing. It must be appropriate for the system's flow rate. Oversized or undersized valves can waste energy or fail to protect equipment. Ensure that the valve material is suitable for the media it will handle. Corrosive substances require specific materials to prevent deterioration.

Flow direction is also key. Some valves only work in certain orientations. This detail often gets overlooked, but it can affect performance. Additionally, consider the maintenance requirements of the valve. Some designs are more accessible than others. Regular checks help avoid unexpected failures. Reflect on these aspects carefully. Small details can have significant impacts on safety and functionality.

Maintenance of safety relief valves is crucial for effective pressure management. According to industry reports, nearly 30% of valve failures can be attributed to improper maintenance. Regular inspections are key. Check for signs of wear, leaks, or corrosion. These issues can lead to significant performance drops.

To ensure optimal function, scheduling periodic testing is essential. Many experts suggest testing every six months. This frequency helps identify potential problems early. Often, users overlook the valve's settings, which should align with operational parameters. An incorrect setting can result in catastrophic failures.

In addition, cleaning is vital. Dust and debris accumulation can affect operation. However, many technicians neglect this task. They often focus on more obvious issues. Overall, an effective maintenance plan should include comprehensive checks, adjustments, and cleaning. A well-maintained safety valve is a reliable valve.

Safety relief valves are critical for pressure management in industrial systems. Their effectiveness relies on compliance with established regulations and standards. The American Society of Mechanical Engineers (ASME) provides guidelines that ensure safety performance. According to a 2022 report, adhering to these standards can reduce accident risks by up to 50%.

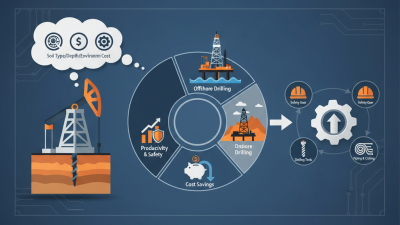

In various industries, including oil and gas, safety relief valves must meet specific codes. The National Board of Boiler and Pressure Vessel Inspectors emphasizes the importance of proper valve selection and installation. Surprisingly, many facilities still overlook these guidelines. This oversight can lead to catastrophic failures. Regular audits are essential. They help identify non-compliance issues.

Moreover, the Occupational Safety and Health Administration (OSHA) mandates that operators maintain safety relief valves regularly. A 2021 survey revealed that 30% of facilities do not conduct adequate maintenance. This gap poses significant safety risks. Effective training programs are necessary to address these deficiencies. By prioritizing regulation adherence, industries can enhance safety and mitigate potential hazards.