In the realm of drilling operations, the effectiveness of drilling mud pumps plays a crucial role in the overall efficiency and safety of the process. Drilling mud pumps are integral to maintaining the circulation of drilling fluids, which not only help to stabilize wellbore conditions but also facilitate the removal of cuttings from the drilling site. According to a report by the American Petroleum Institute, the global market for drilling fluid is projected to reach over $8 billion by 2025, reflecting the increasing importance of efficient mud circulation systems, including pumps.

As various types of drilling projects continue to evolve, the demand for reliable and robust pumping solutions has become more pronounced. With advancements in technology, drilling mud pumps have seen significant improvements in performance, energy efficiency, and durability. The International Association of Drilling Contractors highlights that the right selection of drilling mud pumps can lead to reduced operational costs and enhanced well productivity. This article will explore the top five types of drilling mud pumps, delving into their unique characteristics, advantages, and applications in modern drilling practices, providing essential knowledge for industry professionals aiming to optimize their operations.

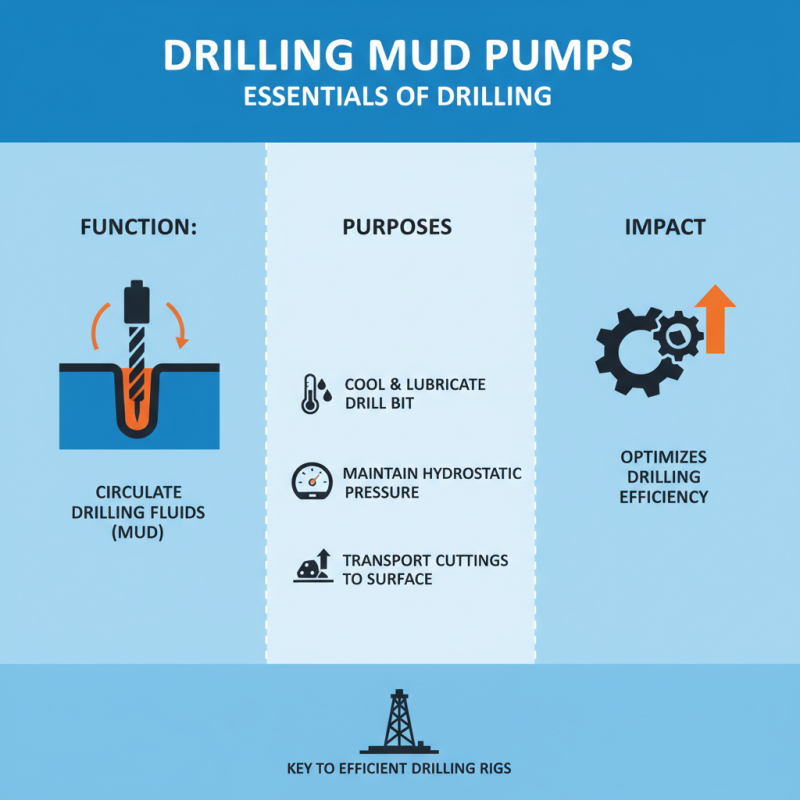

Drilling mud pumps play a crucial role in the drilling industry, primarily by circulating drilling fluids, commonly known as mud. These fluids serve multiple purposes, including cooling and lubricating the drill bit, maintaining hydrostatic pressure, and transporting drilled cuttings to the surface. The efficiency of drilling operations largely depends on the performance of these pumps, making them essential tools on drilling rigs.

There are various types of drilling mud pumps, each designed to tackle specific challenges encountered during drilling operations. Their importance cannot be overstated, as they directly influence the rate of penetration and overall productivity of the drilling process. By ensuring a steady flow of drilling mud, these pumps help to stabilize the borehole and mitigate potential issues such as blowouts, which can arise due to fluctuating pressures. Therefore, understanding the different types of drilling mud pumps and their functionalities is vital for optimizing drilling operations and enhancing safety in the field.

Drilling mud pumps are essential components in the drilling industry, playing a critical role in the circulation of drilling fluid. Understanding the various types of drilling mud pumps can help operators select the most suitable equipment for their specific needs. Generally, drilling mud pumps fall into three main categories: Centrifugal pumps, diaphragm pumps, and positive displacement pumps. Each type has distinct advantages that cater to different operational scenarios.

Centrifugal pumps are prevalent due to their efficiency in high-flow applications, commonly used in exploratory drilling. According to a report by the International Association of Drilling Contractors (IADC), these pumps can achieve flow rates exceeding 1,500 gallons per minute, making them ideal for well control and maintaining optimal pressure during drilling operations.

Conversely, diaphragm pumps are known for their ability to handle more viscous muds, which are often encountered in geologically challenging formations. Their design allows for consistent performance with minimal downtime, optimizing operational efficiency.

Positive displacement pumps are favored in applications requiring the movement of dense slurries. The American Petroleum Institute (API) indicates that these pumps maintain a steady output, regardless of changes in system pressure, making them invaluable in maintaining the necessary mud properties throughout the drilling process.

Understanding these essential categories of drilling mud pumps not only enhances equipment selection but also contributes to overall drilling safety and productivity.

When it comes to selecting a drilling mud pump, understanding the key features and specifications of different types is crucial for optimizing performance and efficiency in drilling operations. Centrifugal pumps are widely appreciated for their simplicity and ability to handle large volumes of fluid. They typically feature a single or multi-stage impeller design, which allows for high flow rates, but they may struggle with the high viscosities often found in drilling mud.

Positive displacement pumps, on the other hand, excel in high-pressure situations and are known for their steady flow rates regardless of the system’s pressure changes. This pump type is characterized by its configuration—such as gear or diaphragm styles—allowing for high efficiency with thick fluids. Additionally, triplex and duplex pumps are particularly popular in the drilling sector due to their robust construction and reliability. With three or two cylinders respectively, these pumps offer excellent suction capabilities and consistent discharge performance, making them ideal for challenging drilling environments.

Submersible pumps are designed for lower depth projects and typically come with built-in motors to save space and enhance portability. Their underwater operation means they can effectively handle varying mud densities while maintaining pressure. Lastly, mud agitators can complement these pumps by ensuring proper mixing and circulation of the drilling fluid, which is essential for optimal performance. By understanding each pump type's specific capabilities, operators can make informed decisions tailored to their project needs.

When selecting drilling mud pumps, understanding the advantages and disadvantages of various types is crucial. Centrifugal pumps, known for their simplicity and efficiency, are widely used for low-viscosity fluids. They can operate at high speeds, offering continuous flow and requiring minimal maintenance. However, their performance diminishes with thicker muds, which can hinder their application in more demanding drilling environments.

On the other hand, positive displacement pumps, including diaphragm and gear pumps, excel in handling high-viscosity fluids. These pumps provide a consistent flow rate regardless of the pressure differential, making them ideal for challenging conditions. However, they typically require more maintenance and can be more expensive than centrifugal pumps. The choice ultimately depends on the specific requirements of the drilling operation, including fluid characteristics and environmental conditions. Understanding these pros and cons will help in making an informed decision that aligns with operational goals.

In the oil and gas industry, maintaining drilling mud pumps is crucial for ensuring operational efficiency and safety. Regular maintenance practices can significantly extend the lifespan of these pumps, which typically face high wear rates due to the harsh conditions of drilling environments. According to a report by the Society of Petroleum Engineers, improper maintenance can increase the risk of pump failure by up to 30%, leading to costly downtime and decreased productivity. Therefore, implementing a routine maintenance schedule that includes inspections, oil changes, and seal replacements is essential for optimal performance.

Operational best practices further enhance the efficiency of drilling mud pumps. Properly monitoring the mud viscosity and density can help in adjusting the pump rates to match the specific drilling conditions, thereby minimizing energy consumption. A recent study by the International Association of Drilling Contractors (IADC) highlighted that optimizing pump performance can lead to a 15% reduction in energy costs. Additionally, regular training for the operational team on the latest technologies and techniques related to drilling mud pumps can improve overall efficiency, as well-trained personnel are better equipped to detect issues early and maintain high operation standards. By focusing on these best practices, companies can ensure that their drilling operations remain both effective and economical.

| Pump Type | Flow Rate (GPM) | Pressure Range (psi) | Maintenance Frequency | Operational Notes |

|---|---|---|---|---|

| Centrifugal Pump | 50-500 | 50-150 | Weekly | Ideal for low-viscosity fluids. |

| Positive Displacement Pump | 10-300 | 100-300 | Monthly | Effective for high-viscosity fluids. |

| Triplex Pump | 30-800 | 100-500 | Biweekly | High efficiency and pressure capabilities. |

| Diaphragm Pump | 5-200 | 50-200 | As needed | Great for abrasive and corrosive fluids. |

| Gear Pump | 20-300 | 50-150 | Monthly | Consistent flow for low to medium viscosity. |