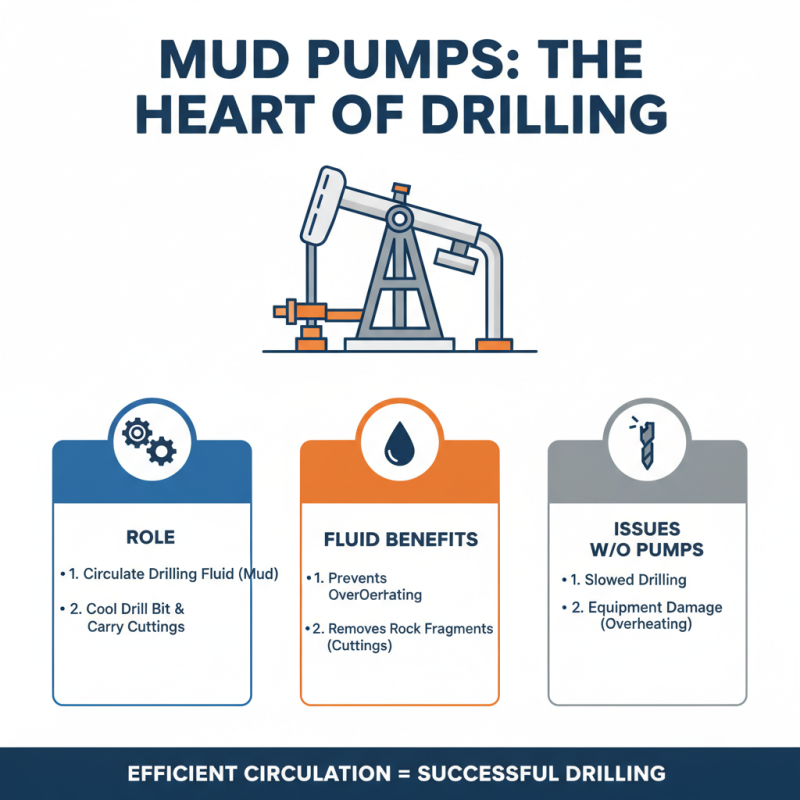

Oilfield Mud Pumps play a crucial role in the drilling process. These pumps are vital for circulating drilling fluid, known as mud. This fluid carries rock cuttings to the surface and cools the drill bit. A proper understanding of these pumps can enhance drilling efficiency significantly.

Several types of Oilfield Mud Pumps exist, each with unique characteristics. Positive displacement pumps and centrifugal pumps are commonly used. Their different designs cater to various drilling needs. Choosing the right pump requires careful consideration. Factors like the well depth, mud characteristics, and required flow rates matter greatly.

However, not every pump will suit every situation. Mistakes in selection can lead to inefficiencies. This may result in increased costs and downtime. Understanding the nuances of each type of Oilfield Mud Pump can prevent such issues. A well-informed decision can optimize performance in the toughest drilling environments.

Mud pumps play a vital role in oilfield operations. They circulate drilling fluids through the wellbore. Their efficiency directly influences drilling performance and safety. According to industry reports, approximately 30% of drilling incidents are linked to inadequate mud pump performance.

There are several types of mud pumps, each with unique functionalities. Triplex pumps are common and known for their durability. They operate with three cylinders, providing consistent flow rates. This type is favored for high-pressure applications. However, they can experience wear over time, leading to maintenance challenges.

Another type is the duplex pump, with two cylinders for enhanced efficiency. These pumps are less common but can reduce the risk of downtime. Sand and solid particles in the drilling fluid can cause clogs, affecting pump efficiency. Understanding these factors is crucial for successful drilling operations. Efficiency relies on selecting the right pump type and regular inspections. Inadequate attention to these issues may result in costly delays and safety hazards.

Mud pumps play a crucial role in drilling operations. They circulate drilling fluid, also known as mud, through the system. This fluid cools the drill bit and carries cuttings to the surface. Without effective mud pumps, the drilling process would slow down significantly. Inadequate fluid circulation can lead to various issues. These issues include overheating and eventually damaging the drill.

Different types of mud pumps exist, each serving specific needs. Positive displacement pumps are commonly used for their robust performance. They create a constant flow, which is essential for maintaining pressure. While these pumps are efficient, they can also be prone to wear and require regular maintenance. This maintenance can sometimes be neglected, leading to reduced efficiency in drilling operations.

Another consideration is selecting the right pump for the specific drilling environment. Factors such as mud viscosity and the depth of the well are critical. A mismatched pump can lead to lower performance and increased costs. Drilling teams must be vigilant in monitoring pump performance. Small issues can escalate quickly if not addressed. Continuous evaluation ensures that drilling efficiency remains high.

When it comes to drilling operations, two prominent types of mud pumps are the triplex and duplex pumps. Both play a crucial role in the circulation of drilling fluids.

Triplex pumps feature three cylinders, enabling them to deliver a more consistent flow rate. This design helps to maintain the pressure needed for effective drilling. The three-piston arrangement also allows for a smoother operation, reducing wear and tear on the pumping components.

On the other hand, duplex pumps have two cylinders and can handle a larger volume of fluid. They are often chosen for projects requiring high flow rates. However, their flow is less uniform compared to triplex pumps. This instability can sometimes lead to challenges in maintaining pressure during critical drilling phases.

Operators must weigh the advantages against potential drawbacks, such as increased maintenance needs. In high-demand scenarios, these differences become more significant. Understanding the specifics of each pump type is essential for optimizing drilling efficiency and effectiveness.

When considering mud pump types, three primary choices stand out: triplex, duplex, and piston pumps. Triplex pumps are highly popular in the oilfield. They can handle high pressure, making them effective for deep drilling. Data reports indicate a triplex pump can reach pressures above 7,000 psi. However, they are complex, requiring regular maintenance. This can lead to downtime—an issue in urgent drilling operations.

Duplex pumps offer simplicity. Their design has fewer moving parts, which reduces maintenance needs. Reports suggest duplex pumps are easier to repair, often resulting in lower operational costs. Yet, their efficiency drops in high-pressure scenarios. For depths beyond 15,000 feet, their performance may lag behind triplex pumps.

Piston pumps present a different set of benefits and challenges. Known for high efficiencies, they are useful in specific applications. However, they may struggle with abrasive fluids. Industry data indicates these pumps can wear out quickly in harsh environments. Thus, while piston pumps excel in efficiency, longevity can be a significant concern. Each type has its merits, but operational needs must guide the choice.

| Mud Pump Type | Advantages | Disadvantages | Common Applications |

|---|---|---|---|

| Horizontal Mud Pumps | Compact design, lower maintenance. | Limited flow rates compared to vertical pumps. | Shallow drilling operations. |

| Vertical Mud Pumps | Higher flow rates, durable. | Larger footprint, higher operational costs. | Deep drilling projects, oil and gas extraction. |

| Diaphragm Pumps | Excellent sealing, reduces leak risks. | Lower flow rates, sensitivity to viscosity changes. | Chemical and viscous fluid applications. |

| Progressing Cavity Pumps | Handles viscous fluids well, continuous flow. | Higher initial costs, requires precise alignment. | Heavy oil recovery, wastewater treatment. |

Choosing the right mud pump is crucial for successful drilling projects. Consider the pump’s capacity. It should match your drilling requirements. A pump that is too small can lead to inefficiencies. On the other hand, an oversized pump may waste resources and increase costs.

Another essential factor is the pump type. Different pump types offer varying benefits. Positive displacement pumps provide steady flow rates. They can handle thick fluids but may struggle with lighter ones. Centrifugal pumps are easier to maintain. However, they may not be suitable for all types of mud.

Don’t overlook maintenance needs. Some pumps require more upkeep than others. Regular maintenance can prevent downtime. It’s wise to assess the skill level of your team as well. If training is needed to operate the pump, this could impact your project timeline. Take these factors into account. Making the right choice is not always straightforward, but careful consideration can lead to better outcomes.