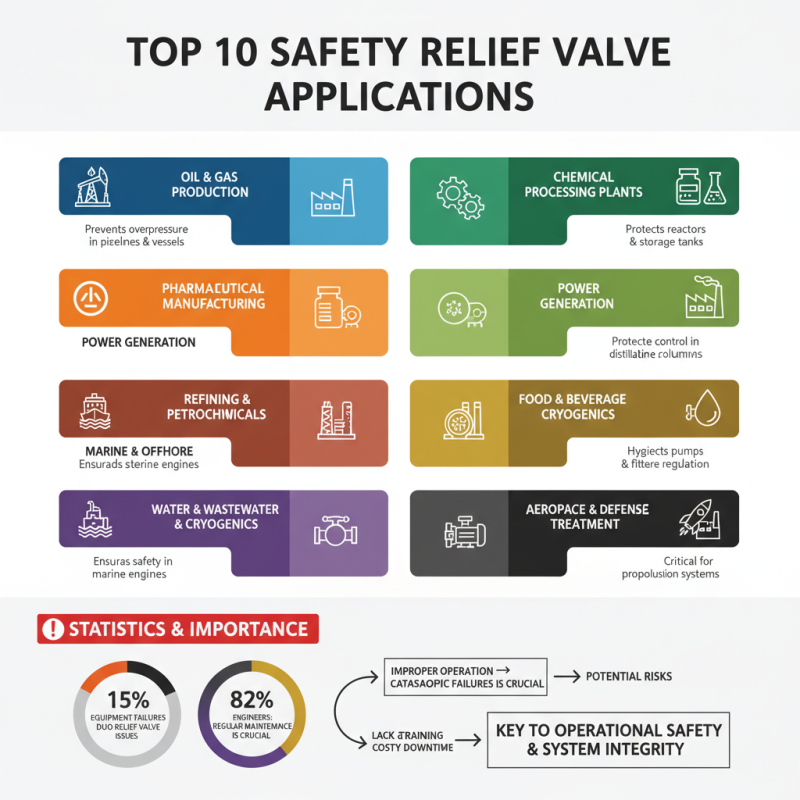

In various industries, the importance of a Safety Relief Valve cannot be overstated. Reports indicate that improper valve operation can lead to catastrophic failures, resulting in costly downtime and safety hazards. Approximately 15% of equipment failures in chemical plants are due to relief valve issues. This statistic emphasizes the need for awareness around safety relief valve applications.

Industries utilize safety relief valves for a range of critical applications. From oil and gas to pharmaceuticals, these valves protect systems from overpressure scenarios. In a recent survey, 82% of engineers acknowledged that regular maintenance of safety relief valves is crucial for system integrity. However, many organizations still overlook this aspect, leading to potential risks.

Understanding the top applications of safety relief valves is vital for enhancing operational safety. These devices play a key role in preserving the reliability of pressure vessels and preventing accidents. Yet, the frequent lack of training on their use and maintenance can be troubling. By addressing these gaps, industries can improve safety and performance, elevating overall standards.

Safety relief valves play a crucial role in various industrial applications. They are designed to protect equipment from overpressure situations. An overpressure condition can lead to catastrophic failures, resulting in injuries and severe damage. These valves release excess pressure, ensuring systems operate safely.

In chemical processing, safety relief valves are essential. They prevent explosive reactions by venting pressure during emergencies. Similarly, in oil and gas sectors, these valves safeguard pipelines and tanks. They mitigate risks of spills and leaks. Many industries rely on them without fully understanding their importance. This lack of awareness can lead to dangerous situations.

Investing in quality training for staff is necessary. Many overlook regular maintenance checks for safety relief valves. Inadequate testing can compromise safety. Workers should recognize that a single failure may have dire consequences. Awareness of safety relief valves is not just beneficial; it’s essential for workplace safety.

Safety relief valves are critical in the chemical processing industry. They prevent overpressure situations that can lead to catastrophic failures. According to a 2022 report by the Chemical Safety Board (CSB), over 50% of incidents in chemical plants can be traced back to pressure issues. This highlights the need for effective safety measures.

In applications like refining and petrochemicals, safety relief valves are essential. They protect equipment such as reactors and separators. A malfunction can lead to leaks or explosions. The U.S. Occupational Safety and Health Administration (OSHA) estimates that proper valve sizing can reduce the risk of such incidents by up to 30%. Accurate sizing is crucial but often overlooked. Many engineers still underestimate the complexities involved in fluid dynamics.

Furthermore, in the pharmaceutical sector, compliance is non-negotiable. Any failure might not only cause financial loss but also harm lives. Safety relief valves play a significant role in maintaining product integrity. Regular maintenance is often neglected, leading to reduced efficiency and increased risk. The industry must address these oversights to ensure safety and reliability.

Safety relief valves play a crucial role in oil and gas production facilities. These devices prevent overpressure by releasing excess gas or liquid. In environments where equipment operates under high pressure, the significance of safety relief valves cannot be overstated. They mitigate the risk of catastrophic failures, protecting both the facility and its workers.

In oil and gas operations, safety relief valves are often installed on various equipment. Separators, compressors, and storage tanks are prime examples. These valves ensure that pressure levels remain within safe limits. A malfunction could lead to spills or explosions. Regular maintenance is essential, yet often overlooked. Staff may not check these valves frequently enough. This negligence can create dangerous conditions.

Monitoring and testing these valves is vital. Facilities need to comply with safety regulations. Sometimes, training staff on the importance of these valves can be neglected. Inadequate training leads to a lack of awareness. This can result in improper handling during emergencies. Creating a culture of safety requires conscious effort. Only then can the integrity of oil and gas production environments be maintained.

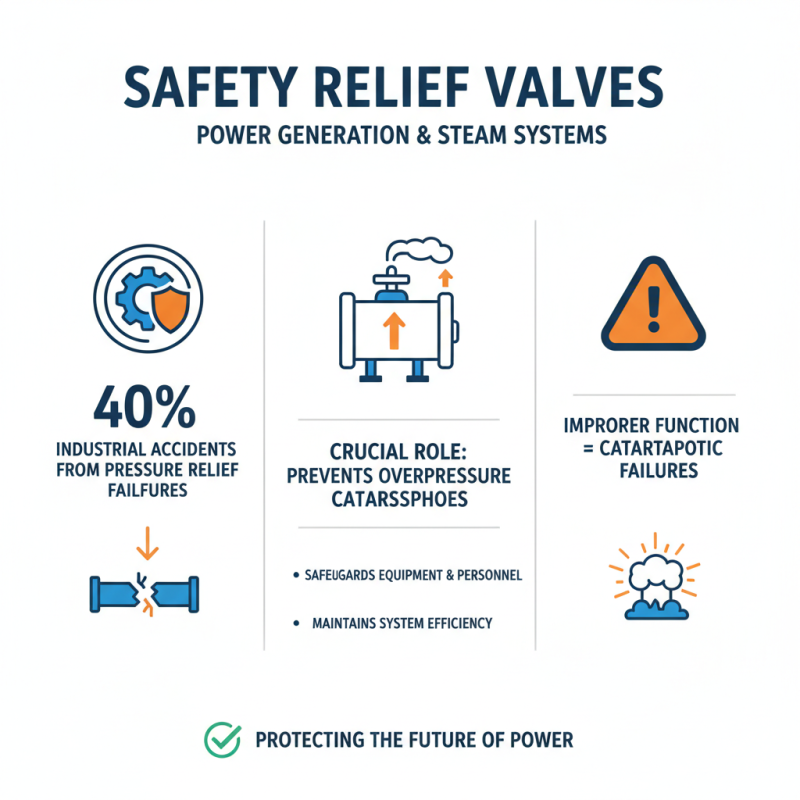

Safety relief valves play a crucial role in power generation and steam systems. They safeguard equipment and personnel from overpressure situations. In steam systems, maintaining pressure is vital for efficiency. According to industry reports, improper functioning of these valves can lead to catastrophic failures. Approximately 40% of industrial accidents stem from pressure relief failures.

In power generation, pressure control is essential. Steam boilers operate under high pressure, often exceeding 150 psi. If a boiler loses control, the consequences can be severe. Data shows that the average cost of a pressure relief valve failure can reach up to $1 million. This figure includes repairs, downtime, and safety assessments. Regular maintenance of these valves is crucial but often overlooked.

While technology has advanced, human error remains a significant issue. Operators may ignore warning signs or neglect routine checks. The American Society of Mechanical Engineers (ASME) emphasizes that nearly 30% of pressure relief valve failures are due to incorrect installation. Understanding these risks can improve safety and performance in steam systems. The focus should remain on both technology and human factors to enhance safety outcomes.

Safety relief valves play a crucial role in pharmaceutical manufacturing processes. These valves prevent over-pressurization by releasing excess pressure. If pressure builds up too much, it can lead to dangerous situations. In this environment, precision is vital for safety.

In a typical manufacturing setup, safety relief valves are placed on reactors and storage vessels. They monitor pressure and provide immediate response if levels surpass safe limits. Regular maintenance is essential. Neglecting upkeep can lead to valve failures, which are often costly and dangerous.

Moreover, not all safety relief valves are suitable for every application. Choosing the wrong type can have dire consequences. Operators must consider the specific conditions of their processes. This requires a deep understanding of both the machinery and the materials being handled. It’s an area that often lacks attention but is crucial for overall safety.

| Application | Description | Pressure Range (psi) | Temperature Range (°F) | Material |

|---|---|---|---|---|

| Steam Sterilization | Used to relieve excess pressure in steam sterilizers. | 0-150 | 120-250 | Stainless Steel |

| Water Purification | Preventing pressure buildup in water purification units. | 0-100 | 50-140 | PVC |

| Chemical Mixing | Maintaining safety during the chemical reaction process. | 0-200 | 70-180 | Carbon Steel |

| Batch Reactor | Protecting against overpressure in batch reactors. | 0-300 | 50-230 | Hastelloy |

| Drying Processes | Preventing pressure from exceeding design limits in dryers. | 0-150 | 60-180 | Aluminum |

| Distillation | Relieve pressure in distillation columns to avoid explosions. | 0-250 | 80-220 | Teflon |

| Filling Operations | Prevent overpressure during the filling of containers. | 0-100 | 50-150 | Brass |

| Aseptic Processing | Maintaining a sterile environment by managing pressure. | 0-120 | 70-160 | 316L Stainless Steel |

| Product Storage | Preventing overpressure in storage tanks. | 0-200 | 40-200 | Polypropylene |